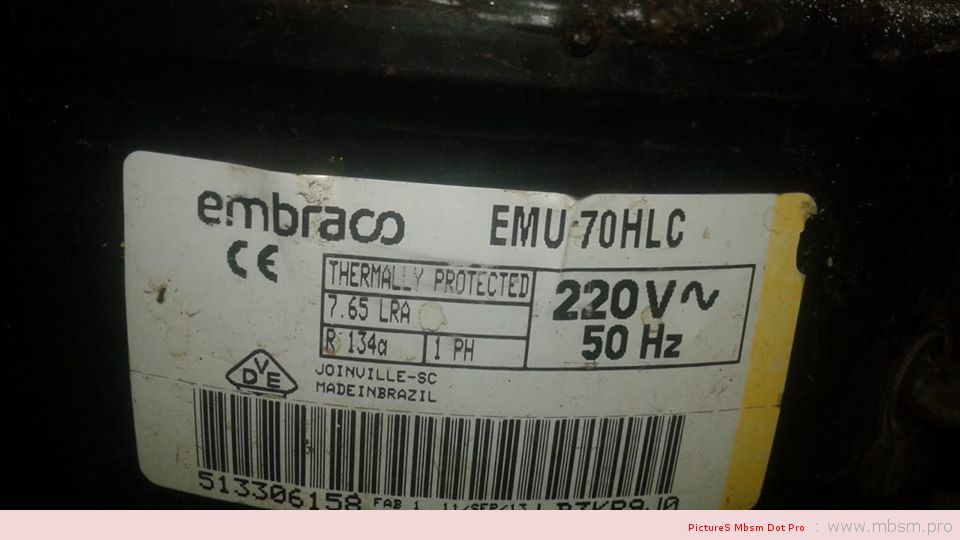

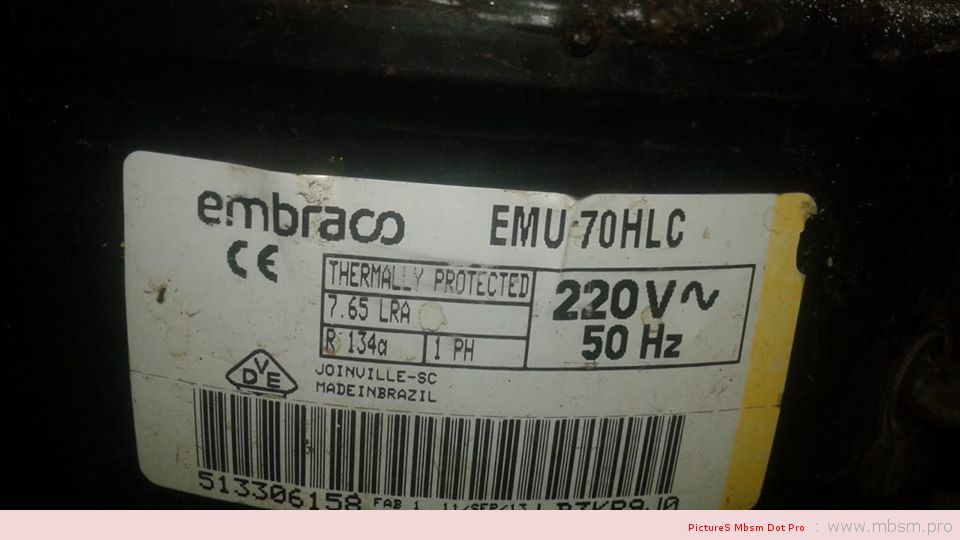

Embraco / Embraco piston compression EMU70HLC detailed parameters:

| Refrigerant: | R-134a | Exhaust volume (cm³): | 5.96 |

| Voltage: | 220 V 50Hz 1 ~ | Lubricating oil category: | ISO10 |

| Frequency (Hz): | 50 | Lubricating oil amount (ml): | 180 |

| application: | LBP | motor model: | RSCR |

| horsepower: | 1/5 | Starting torque: | LST |

| efficiency: | 1.40 | Test type: | ASHRAE32 |

| Cooling capacity: | 165 |

ID: 513306157

Appearance

| shape | Material | Dimensions (mm) | |

| Inhalation interface | Slanted 42? Up + 45 ° to Back | Copper | 6.50 |

| Exhaust interface | Slanted parallet BP + 24 ° to Back | Copper | 4.94 |

| Process interface | Slanted 45 ° up + 45 ° to Back | Copper | 6.50 |

| Oil cooler: | |

| Anchor plate: | European Standard EUEM |

| bracket: | No |

| Weight (kg): | 8.11 |

application

| Maximum ambient temperature (° C): | 43 |

| Expansion device: | Capillary |

| cool down: | Direct cooling |

| Air flow rate: |

Mechanical data

| Bill of materials: | 513306157 |

| Starting torque: | Low starting torque |

| Bore (mm): | 22.50 |

| Stroke (mm): | 7.50 |

| Weight (kg): | 8.11 |

digital data

| motor model: | RSCR |

| Wire group resistance (25 ° C)-start (25 ° C)-start: | 14.95 |

| Wire group resistance (26 ° C)-operation (25 ° C)-operation: | 17.98 |

Checkpoint-Condensation temperature 54.4 ° C

| Evaporation temperature | Cooling capacity +/- 5% | Energy consumption +/- 5% | Now energy efficiency +/- 5% | Energy efficiency +/- 7% | ||||

| ° C | (kcal / h) | (W) | (Btu / h) | (W) | (A) | (kcal / Wh) | (W / W) | (Btu / Wh) |

| -23.3 | 142 | 165 | 563 | 118 | 0.69 | 1.21 | 1.40 | 4.79 |

Condensation temperature 35 ° C

| Evaporation temperature | Cooling capacity +/- 5% | Energy consumption +/- 5% | Now energy efficiency +/- 5% | Gas flow rate +/- 5% | Energy efficiency +/- 7% | ||||

| ° C | (kcal / h) | (W) | (Btu / h) | (W) | (A) | (kg / h) | (kcal / Wh) | (W / W) | (Btu / Wh) |

| -35 | 77 | 89 | 304 | 83 | 0.57 | 1.72 | 0.93 | 1.08 | 3.68 |

| -30 | 115 | 133 | 455 | 97 | 0.62 | 2.58 | 1.18 | 1.37 | 4.67 |

| -25 | 157 | 182 | 622 | 111 | 0.67 | 3.53 | 1.42 | 1.65 | 5.62 |

| -20 | 203 | 236 | 804 | 123 | 0.70 | 4.57 | 1.65 | 1.92 | 6.56 |

| -15 | 252 | 293 | 1.000 | 133 | 0.73 | 5.71 | 1.89 | 2.20 | 7.52 |

| -10 | 305 | 354 | 1.210 | 142 | 0.75 | 6.93 | 2.14 | 2.49 | 8.50 |

Condensation temperature 45 ° C

| Evaporation temperature | Cooling capacity +/- 5% | Energy consumption +/- 5% | Now energy efficiency +/- 5% | Gas flow rate +/- 5% | Energy efficiency +/- 7% | ||||

| ° C | (kcal / h) | (W) | (Btu / h) | (W) | (A) | (kg / h) | (kcal / Wh) | (W / W) | (Btu / Wh) |

| -35 | 63 | 74 | 252 | 82 | 0.57 | 1.42 | 0.77 | 0.90 | 3.06 |

| -30 | 101 | 117 | 399 | 98 | 0.62 | 2.26 | 1.03 | 1.20 | 4.08 |

| -25 | 144 | 168 | 573 | 113 | 0.67 | 3.26 | 1.28 | 1.49 | 5.08 |

| -20 | 195 | 227 | 773 | 128 | 0.72 | 4.40 | 1.52 | 1.77 | 6.05 |

| -15 | 251 | 292 | 998 | 143 | 0.77 | 5.70 | 1.76 | 2.05 | 7.00 |

| -10 | 314 | 365 | 1.247 | 158 | 0.82 | 7.14 | 1.99 | 2.32 | 7.91 |

Condensation temperature 55 ° C

| Evaporation temperature | Cooling capacity +/- 5% | Energy consumption +/- 5% | Now energy efficiency +/- 5% | Gas flow rate +/- 5% | Energy efficiency +/- 7% | ||||

| ° C | (kcal / h) | (W) | (Btu / h) | (W) | (A) | (kg / h) | (kcal / Wh) | (W / W) | (Btu / Wh) |

| -35 | 55 | 64 | 217 | 80 | 0.57 | 1.23 | 0.68 | 0.79 | 2.71 |

| -30 | 85 | 99 | 337 | 96 | 0.62 | 1.91 | 0.89 | 1.03 | 3.53 |

| -25 | 125 | 145 | 495 | 112 | 0.67 | 2.81 | 1.12 | 1.30 | 4.43 |

| -20 | 174 | 202 | 690 | 129 | 0.72 | 3.93 | 1.35 | 1.56 | 5.34 |

| -15 | 232 | 270 | 920 | 148 | 0.79 | 5.25 | 1.57 | 1.83 | 6.23 |

| -10 | 299 | 347 | 1.185 | 168 | 0.86 | 6.79 | 1.78 | 2.07 | 7.07 |

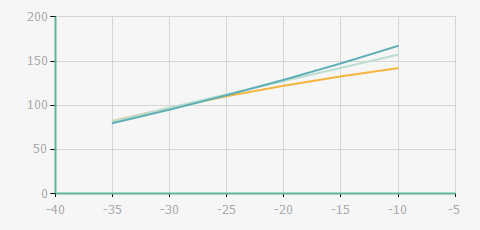

Cooling capacity (W)

Condensing temperature 45 ° C Condensing temperature 55 ° C Condensing temperature 65 ° C

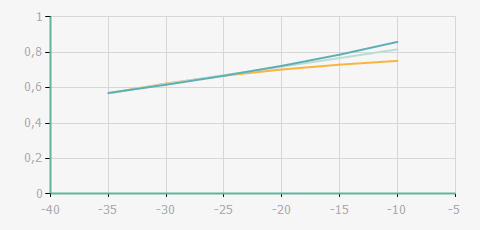

Energy consumption (W)

Condensing temperature 45 ° C Condensing temperature 55 ° C Condensing temperature 65 ° C

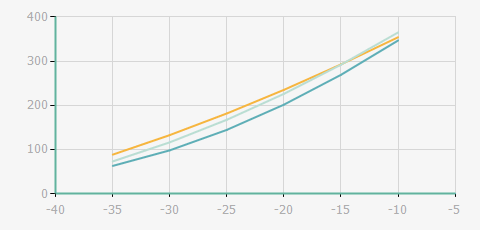

Energy efficiency now (A)

Condensing temperature 45 ° C Condensing temperature 55 ° C Condensing temperature 65 ° C

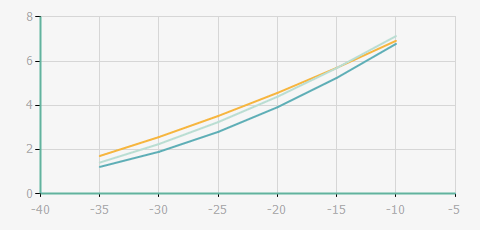

Gas flow rate (kg / h)

Condensing temperature 45 ° C Condensing temperature 55 ° C Condensing temperature 65 ° C

Rubber pad

| Engineering code: | 13146411 |

| Dimensions: | mm (Inch) |

The grommets are made of special rubber and used in the nut and bolt type or in the snap on type assembly. The rummer grommet. The dimensions of which are shown in the figure below. Was developed for installation in compressors with 16 and 19 mm diameters holes in the base plate.

Embraco / Embraco piston compression product list:

Embraco is an expert and leader in refrigeration solutions for the light commercial sector. The solutions we provide for the light business field can ensure a high degree of reliability of products while saving energy, thereby providing a higher quality of life.

Technology leadership, operational excellence and sustainability are the strategic pillars that ensure Embraco surpasses other companies in the global market. Embraco has developed the Fullmotion all-drive frequency conversion technology, which can release different cooling capacity according to the load to achieve up to 40% energy saving.

The global annual output exceeds 38 million, and the solutions provided by the company are known for their innovation and low energy consumption. They have always led the market trend and supported the company’s continuous innovation and development. Embraco employs nearly 12,000 people in factories and offices in Brazil (headquarters), China, Italy, Slovakia, Mexico, the United States, and Russia.

Embraco data

-Embraco can produce more than 37 million compressors per year. As of 2010, the Brazil plant alone had produced more than 300 million compressors.

-During its 40 years of operation, Embraco products are sold to more than 80 countries and regions around the world.

-Embraco employs approximately 12,000 employees in six countries (Brazil, China, Italy, Slovakia, United States, Mexico and Russia).

-Embraco has obtained a total of 1277 patents.

-A team of more than 500 engineers and technicians dedicated to providing solutions to the world’s leading manufacturers of household and commercial refrigeration equipment.

-Embraco is one of the companies that has obtained multiple patents from Brazil’s National Institute of Industrial Property (INPI) in recent years.

High energy efficiency

Energy efficiency is the basis for the development of all Embraco products. This means developing and producing compressors with lower energy consumption and less raw materials, while maintaining the benchmark quality of the products. Therefore, we continue to invest in research and development to create more efficient and quieter products that are harmless to the environment. As a result of our efforts to improve the energy efficiency of our products, and in order to exceed the highest expectations of our customers, we have developed Embraco all-wheel drive compressors, a type that can change the cooling capacity according to the speed of rotation, which can reduce energy consumption by 40%.

We have a full range of products that can provide compressors with different levels of energy efficiency. The solutions we provide are a global benchmark in meeting the most stringent international energy consumption standards. Pursuing continuous improvement of products and processes is a commitment, and each generation of Embraco compressors will be more efficient than previous products.

Green solution

Embraco has always been committed to providing the market with green solutions that subvert the traditional. We are already ahead of the industry, for example, providing advanced products that use environmentally friendly refrigerants. We have been manufacturing compressors using natural refrigerants R290 and R600a for more than 20 years. These natural refrigerants are very ideal refrigerants, which will not damage the ozone layer and will not produce a greenhouse effect. In addition, it has the advantages of low noise, high energy efficiency, and large cooling capacity, which can meet the most stringent environmental requirements.

| Attachment | Type | Link |

|---|---|---|

| Mbsm_dot_pro_private_picture_EMU70HLC | image/jpeg | Get Link |

| Mbsm_dot_pro_private_picture_EMU70HLC_2 | image/gif | Get Link |

| Mbsm_dot_pro_private_picture_EMU70HLC_1 | image/gif | Get Link |

| Mbsm_dot_pro_private_picture_EMU70HLC_1 | image/gif | Get Link |

| Mbsm_dot_pro_private_picture_EMU70HLC-1 | image/jpeg | Get Link |

| Mbsm_dot_pro_private_picture_EMU70HLC_2-1 | image/gif | Get Link |

| Mbsm_dot_pro_private_picture_EMU70HLC_3 | image/gif | Get Link |

| Mbsm_dot_pro_private_picture_EMU70HLC_4 | image/gif | Get Link |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |