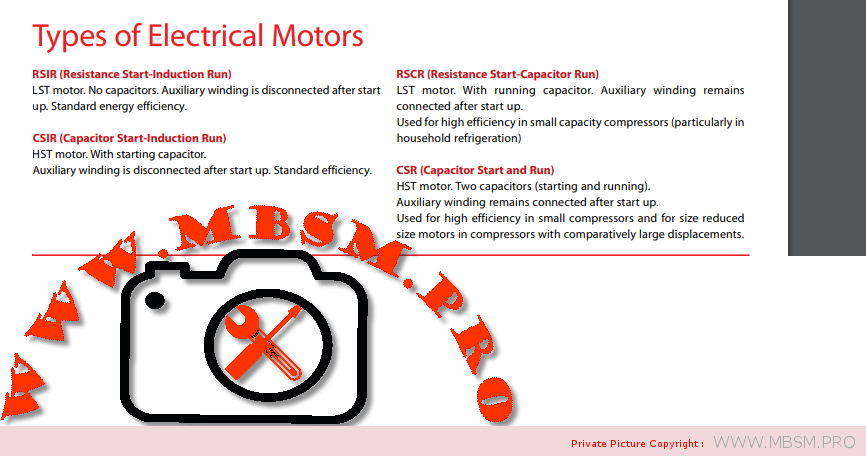

Types of Electrical Motors

RSIR (Resistance Start-Induction Run)

LST motor. No capacitors. Auxiliary winding is disconnected after start

up. Standard energy efficiency.

CSIR (Capacitor Start-Induction Run)

HST motor. With starting capacitor.

Auxiliary winding is disconnected after start up. Standard efficiency.

RSCR (Resistance Start-Capacitor Run)

LST motor. With running capacitor. Auxiliary winding remains

connected after start up.

Used for high efficiency in small capacity compressors (particularly in

household refrigeration)

CSR (Capacitor Start and Run)

HST motor. Two capacitors (starting and running).

Auxiliary winding remains connected after start up.

Used for high efficiency in small compressors and for size reduced

size motors in compressors with comparatively large displacements

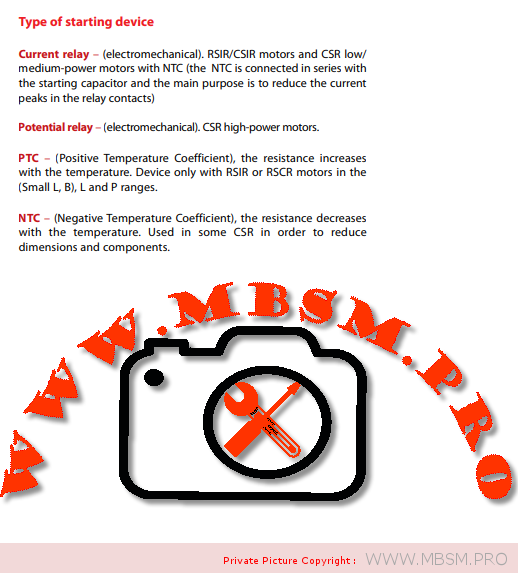

Type of starting device

Current relay – (electromechanical). RSIR/CSIR motors and CSR low/

medium-power motors with NTC (the NTC is connected in series with

the starting capacitor and the main purpose is to reduce the current

peaks in the relay contacts)

Potential relay – (electromechanical). CSR high-power motors.

PTC – (Positive Temperature Coefficient), the resistance increases

with the temperature. Device only with RSIR or RSCR motors in the

(Small L, B), L and P ranges.

NTC – (Negative Temperature Coefficient), the resistance decreases

with the temperature. Used in some CSR in order to reduce

dimensions and components.

Type of torque

LST – Low Starting Torque – Systems with capillary tube or balanced

pressures at start up.

HST – High Starting Torque – Systems with expansion valve or

capillary tube, with unbalanced pressures at start up.

| Attachment | Type | Link |

|---|---|---|

| Mbsm_dot_pro_private_picture_DANFOSS-0 | image/png | Get Link |

| Mbsm_dot_pro_private_picture_DANFOSS-01 | image/png | Get Link |

| Mbsm_dot_pro_private_picture_DANFOSS-02 | image/png | Get Link |

| Mbsm_dot_pro_private_picture_DANFOSS-05 | image/png | Get Link |

| Mbsm_dot_pro_private_picture_DANFOSS-04 | image/png | Get Link |

| Mbsm_dot_pro_private_picture_DANFOSS-03 | image/png | Get Link |

| Mbsm_dot_pro_private_picture_DANFOSS-06 | image/png | Get Link |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

| Image | View Image |

good