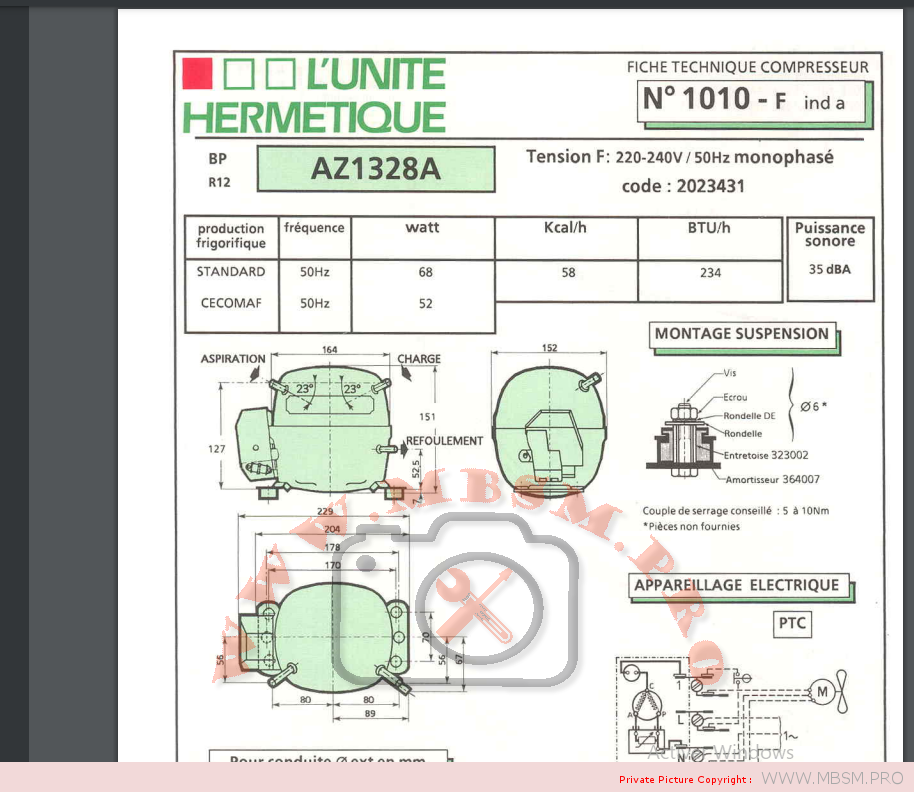

Mbsm.pro, COMPRESSOR, AZ 1328A, 1/10 HP, AZ1328A, 68 w, 58 kcal/h, 234 btu/h, 1 phase, 220 v, r12, TECUMSEH EUROPE

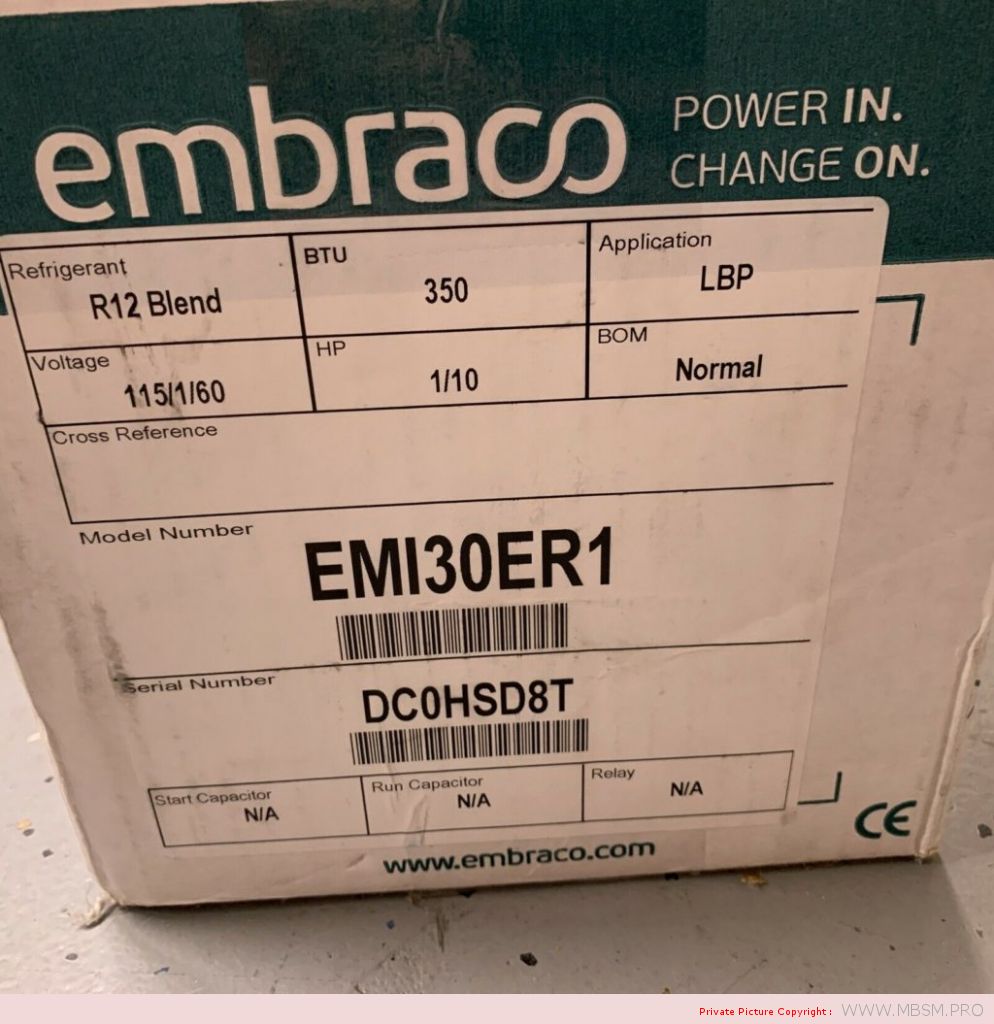

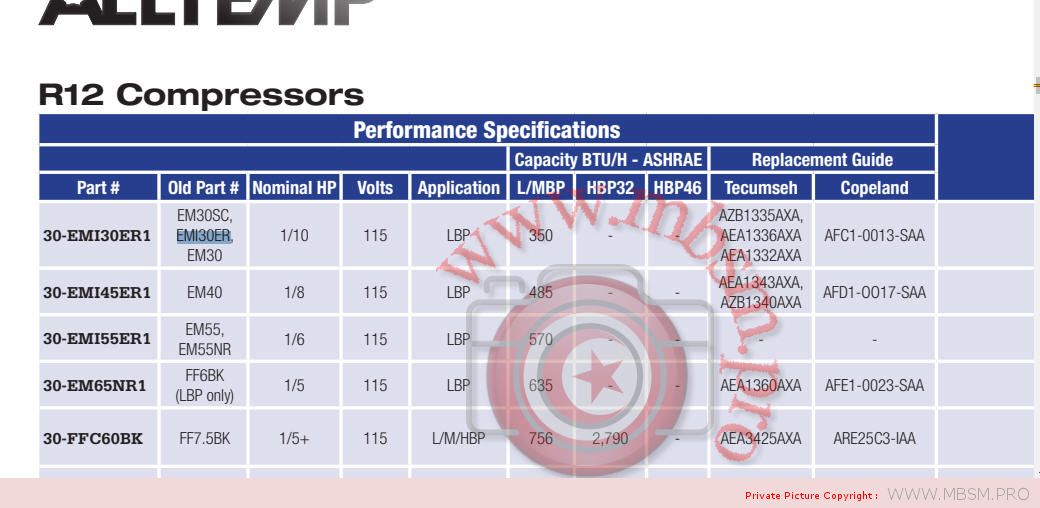

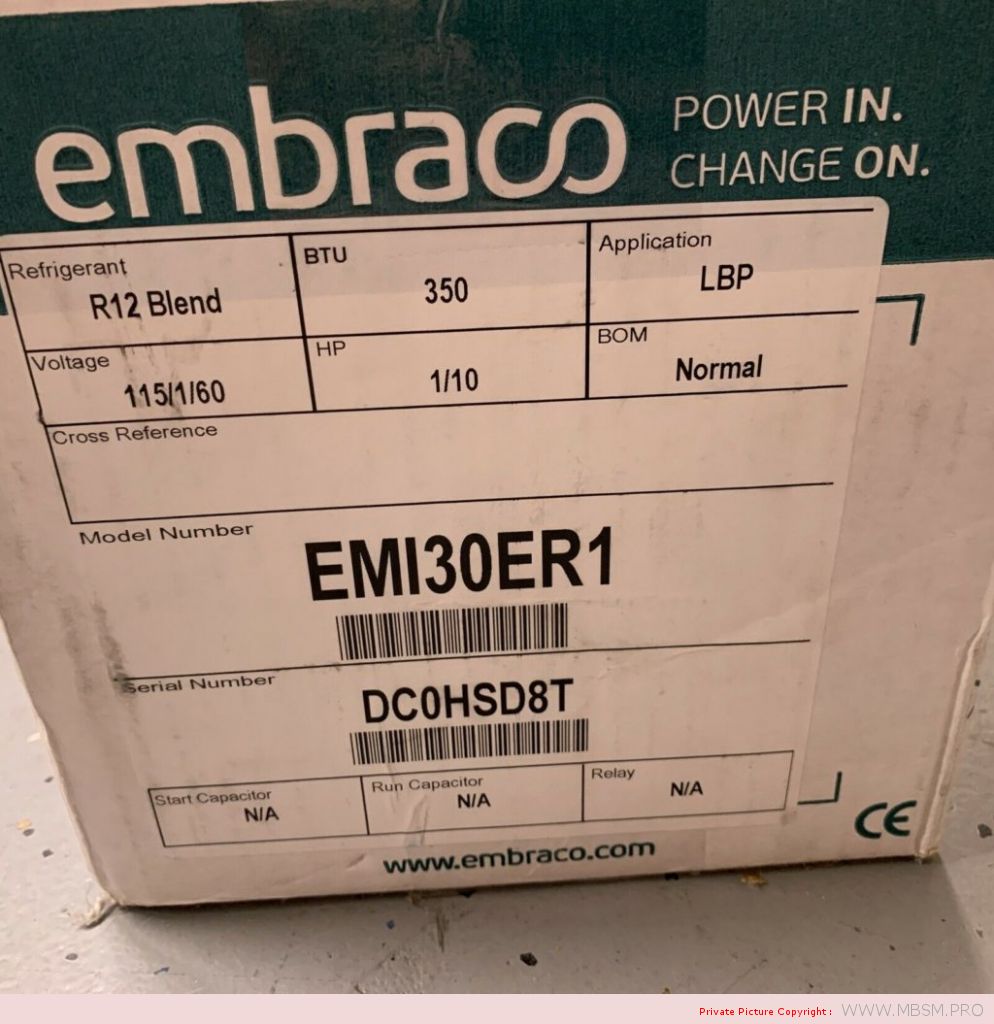

Description350 BTU Compressor Refrigeration 1/10 HP (115V)

Features:

Replaces:

SpecsProduct Type:Compressor

Capacity (BTU):350

Horse Power: 1/10

Voltage: 115v

Phase:1 Hertz:60

Refrigerant Type:R-12

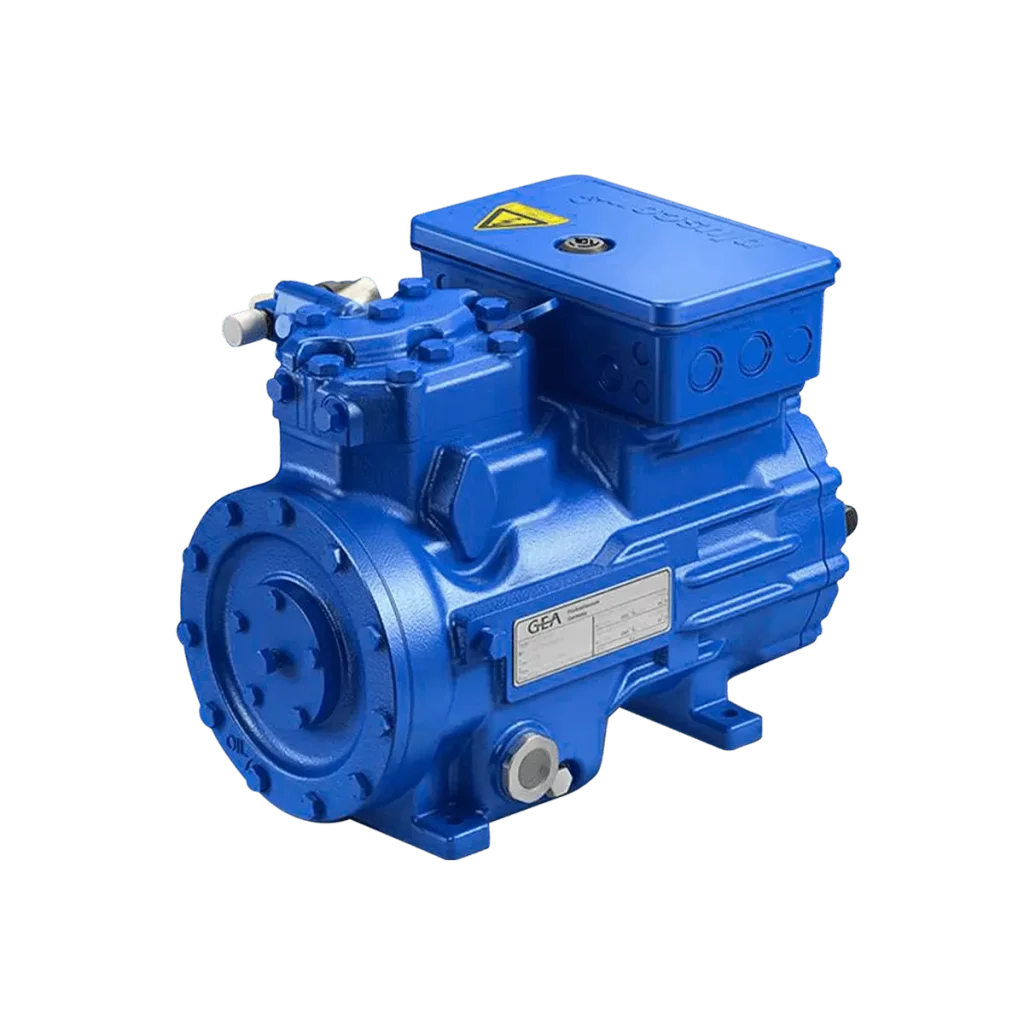

| HGX12P/75-4 R410A |

| Power supply | 220/240 V-380/420 V-50 Hz-3 ph (265/290 V-440/480 V-60 Hz-3 ph) Δ Y |

|---|---|

| Horsepower | 25,0 hp |

| Displacement | 6,70 m3 |

| Cooling capacity at Refrigeration conditions, R407C | 3,39 kW |

| Cooling capacity at Refrigeration conditions, R404A | 3,97 kW |

| Refrigerant | R134a, R404A, R407C, R407F, R448A, R449A, R507, R513A |

| Suction pipe | 5/8″ |

| Discharge pipe | 1/2″ |

| Weight | 49 kg |

| LRA (Δ/y) | 43/25 A |

| MCC (Δ/y) | 8,0/4,6 A |

| Type of oil | FUCHS Reniso Triton SE 55 |

| Other remarks | Available in ATEX version, Electronic frequency control (30-70 Hz), Equipped with oil pump without connections to the differential oil pressure switch |

| Accessories | Control Capacity 50/100%, Crankcase heater 50-120 W, Thermal protection thermostat (PTC sensor) |

| Application | MHBP |

| Technology | Fixed speed |

| Lubrication mode | Oil pump |

| Low pressure design | 19 bar |

| High pressure design | 28 bar |

| Type of motor cooling | Suction gas |

| Protection type | IP 66 |

| Motor protection type | INT69 G |

| Speed | 1450 rpm |

|

| 1) |

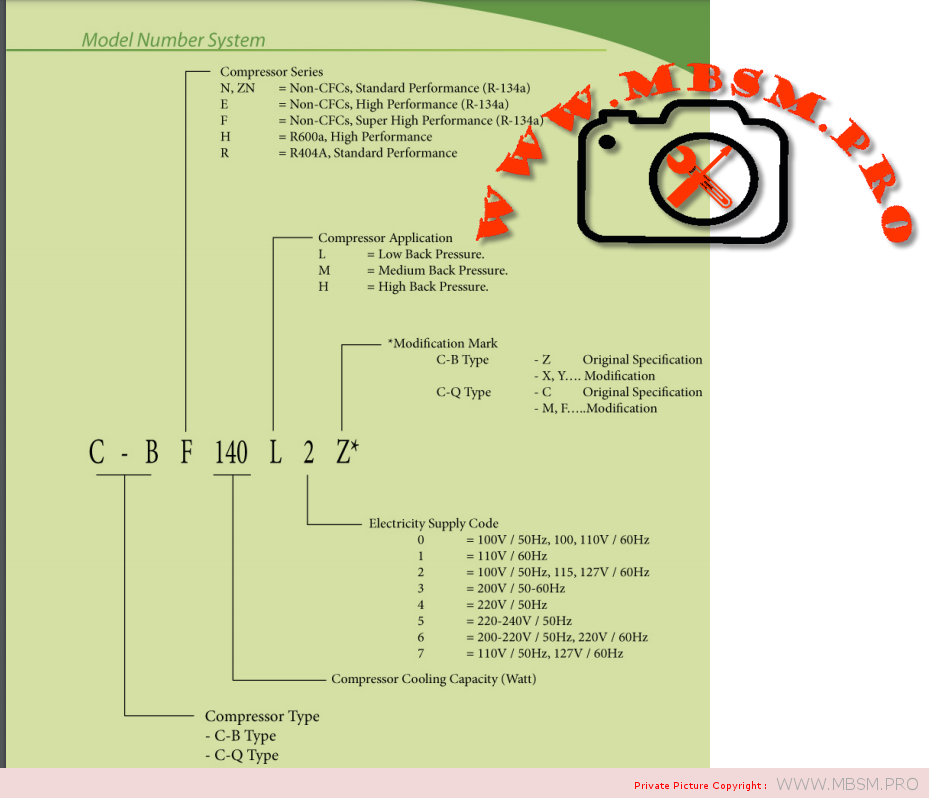

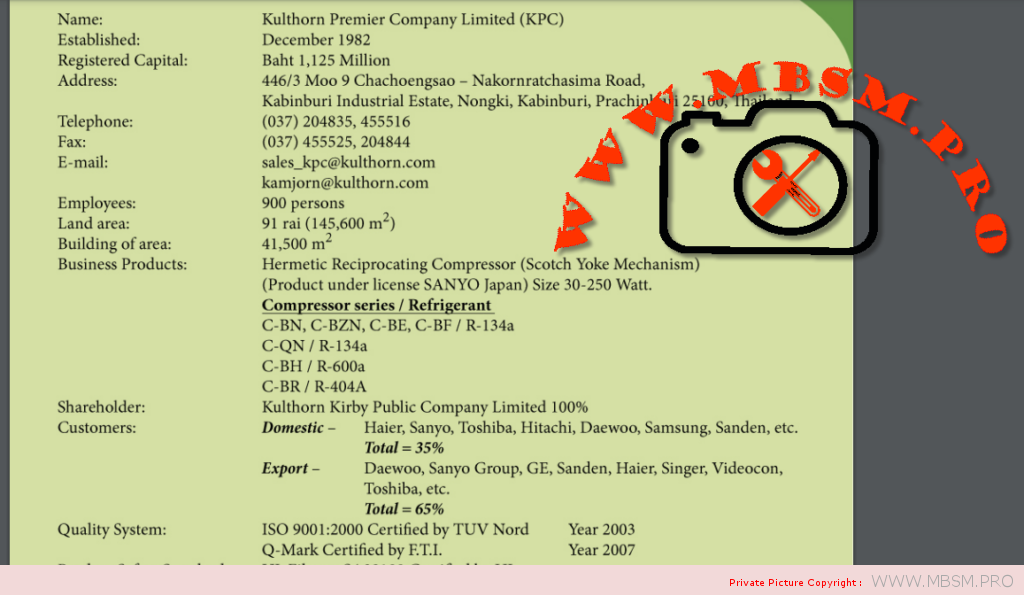

Kulthorn, compressor, Kulthorn compressor, c-qn76l6f, 1/10 Hp, 1Ph, Serie C-q, R134a, 76 watt, Low back pressure, 200-220V/50hz, 220v/60hz, Compressor modefier

Compressor Motor Protectors

Each compressor incorporates a motor protection device or system. Generally, the

larger the compressor, the more sophisticated the motor protector.

It is essential that an electric motor is protected against conditions that could

otherwise result in damage to the motor or to the electrical supply system. For this

reason, every Kulthorn compressor is supplied with a motor protector, sometimes referred

to as an overload. The more expensive the compressor, the greater is the economic

justification for specifying a motor protector that has the ability to protect over a wider

range of conditions.

| Alimentation | 220/240 V-50 Hz-1 ph |

|---|---|

| Chevaux | 1/10 hp |

| Déplacement | 3,97 cm3 |

| Application | LBP |

| Capacité frigorifique en conditions EN12900 MT, R134a | 123 W |

| Capacité frigorifique en conditions ASHRAE pour bassses températures, R134a | 108 W |

| Capacité frigorifique en conditions EN12900 LT, R134a | 54 W |

| Réfrigérant | R134a |

| Aspiration | 1/4″ |

| Refoulement | 1/4″ |

| Poids | 7,5 kg |

| Hauteur | 166 mm |

| LRA | 3,8 A |

| Huile de recharge | 180 cm3 |

| Type d’huile | POE 22 ester |

| Autres remarques | Accessoires de démarrage inclus |

| Technologies | Vitesse fixe |

| Type de refroidissement moteur | Gaz d’aspiration |

| Type moteur | RSIR/RSCR |

| Type protection moteur | Externe |

Compressor Embraco Aspera EMT36HLP / EMY3109Z, LBP – R134a, 220 – 240V/1/50Hz, 1/10+ HP, discharge 3.97 cm3, motor type RSIR, lubricant type POE 22, lubricant charge 180 mlLRA 3.8A, 108 W at -23.3 / +54.4 °C, cooling: static, expan sion device: capillary, weight 7.5 kg

| Refrigerant: | R134a |

| Power range(W): | 0 – 100 W 101 – 200 W |

| Performance range (C): | -35 C to -10 C |

| Working area: | LBP |

| Design type: | Hermetic |

| Model series: | EMT |

| Use with: | Capillary |

| Power range(HP): | 0-2 |

| Power supply: | 230 V |

| Oil type: | POE22 |

| Engine type: | RSIR |

| Article condition: | New |

| Info: | Oil filled |

| Shipping weight: | 8,50 Kg |

| Contents: | 1,00 Pieces |

| Dimensions ( length × width × height ): | 22,80 × 15,50 × 16,60 cm |

| Cooling capacity condition: | T0 -25 C, Tk +55 C |

| Manufacturer: | Embraco Aspera |

| Model: | EMT36HLP |

| Stroke volume (cm3): | 3,97 |

| Performance condition: | -23,3 / +54,4 |

| Power (W): | 108 |

| Cooling capacity (W): | 98 |

| Power (HP): | 0,1 |

| Max. Starting current (A): | 3,8 |

| Engine type: | RSIR |

| Note: | Static cooling |

| Oil quantity (l): | 0,18 |

| Compressor type: | Piston |

| Power range: | -35 C to -10 C |

|

Model |

Power(HP) |

Capacity(W) |

COP |

||

|

50Hz |

60Hz |

50Hz |

60Hz |

||

|

220 – 240 V 50/60 Hz |

|||||

|

PW1.5VK |

1/20 |

41 |

49 |

0.73 |

0.79 |

|

PW2.0VK |

1/15 |

52 |

62 |

0.84 |

0.91 |

|

PW2.5VK |

1/12 |

56 |

79 |

0.85 |

0.95 |

|

PW4.0VK |

1/10 |

76 |

102 |

0.96 |

1.05 |

|

PW4.5VK |

1/8 |

108 |

110 |

1.05 |

1.16 |

|

PW5.5VK |

1/5 |

126 |

|

1.15 |

|

|

110 – 120 V 60 Hz |

|||||

|

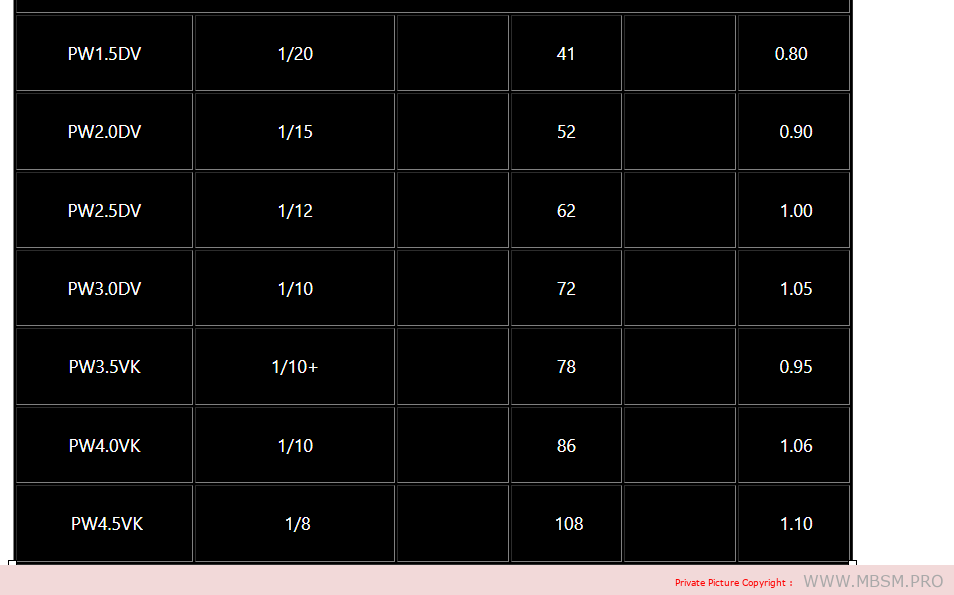

PW1.5DV |

1/20 |

|

41 |

|

0.80 |

|

PW2.0DV |

1/15 |

|

52 |

|

0.90 |

|

PW2.5DV |

1/12 |

|

62 |

|

1.00 |

|

PW3.0DV |

1/10 |

|

72 |

|

1.05 |

|

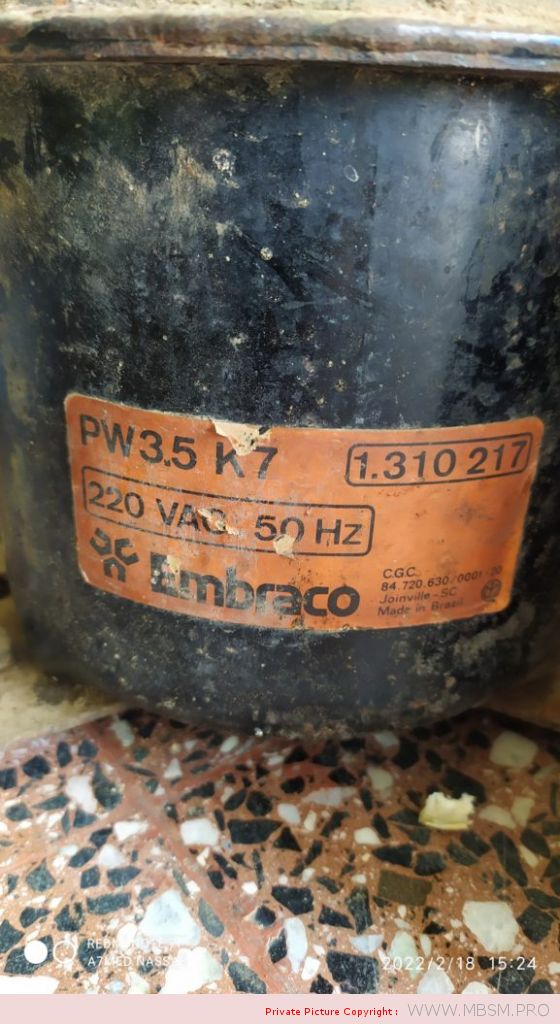

PW3.5VK |

1/10+ |

|

78 |

|

0.95 |

|

PW4.0VK |

1/10 |

|

86 |

|

1.06 |

|

PW4.5VK |

1/8 |

|

108 |

|

1.10 |