Mbsm.pro, Table, starting, capacitors, compressor

▷ Starting and Running Capacitors Table

Do you need to replace a start or run capacitor and you don’t know which one the equipment has? In this post we will give you some tables of start and run capacitors so that you can access it when you need it.

The topic regarding the calculation of capacitors for single-phase compressors is of great importance, because whoever is repairing needs to know when it is in poor condition and also what the replacement of the damaged part will be.

The technician who manipulates the equipment has to know that the new capacitor that he has bought to replace the old one must exactly meet the working voltage or greater than that of the original.

It is also important to highlight in this article that the compressor voltage has almost no relation to the capacitor voltage.

If you do not have the original capacitor data, you can approximate it using the following capacitor values for single-phase motors that we present below.

They can be used as a guide or reference for selecting, replacing capacitors when the exact values are unknown.

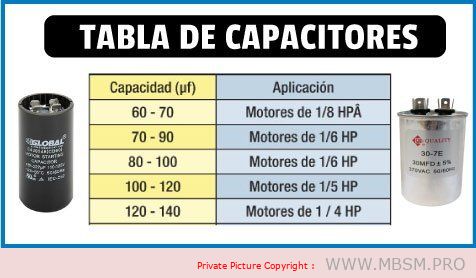

Table of starting capacitors

for single-phase motors

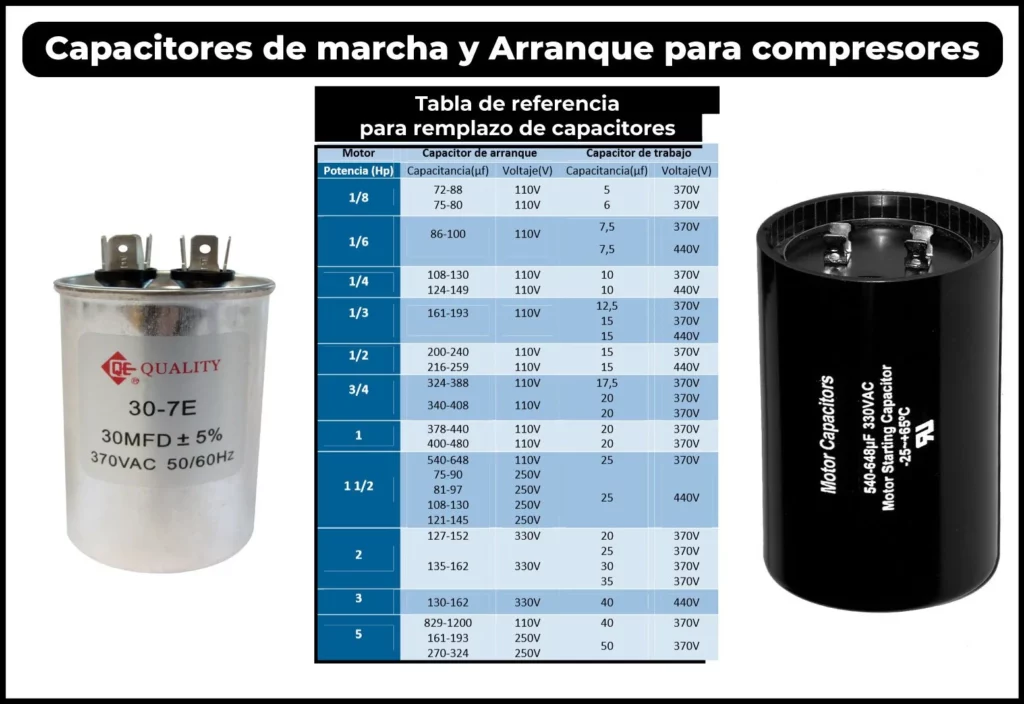

Table of Start and Run Capacitors

for Single Phase Capacitors

In this table, which is very similar to the previous one, I attach capacitor values for single-phase motors.

both working and starting capacitors, this way you will have the most user-friendly information in a single image

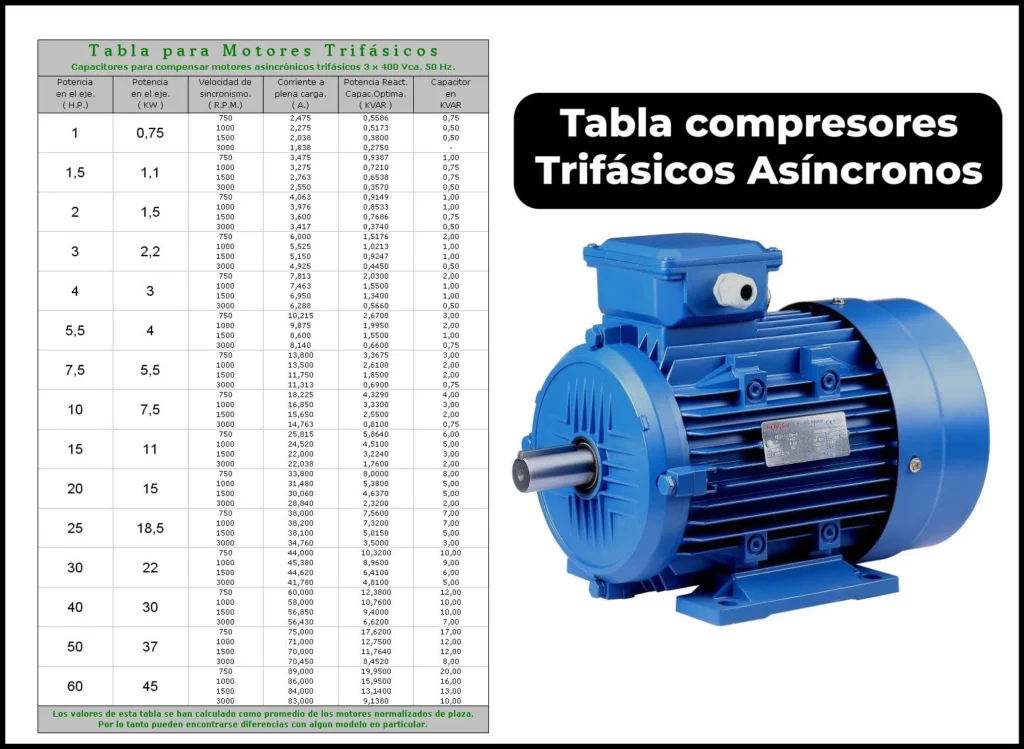

Capacitor Table for

Three-Phase Electric Motors

As a general rule, low-power three-phase electric motors have an operating voltage of 220 VD / 380 VY, but we must always make sure .

To do this, it is best to look at the motor’s nameplate. Where the voltages and connection will be indicated to know the type of Capacitor they use.

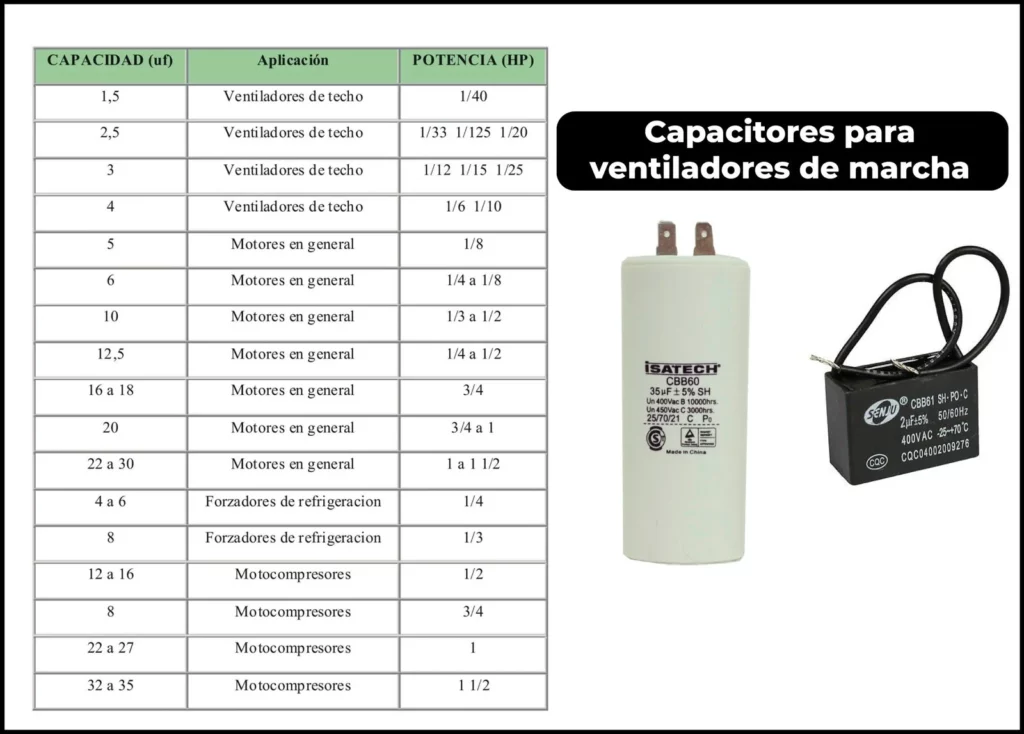

Fan run capacitor table

If you need to change a running or permanent fan capacitor, this table attached below can guide you to resolve the fault of the equipment you are repairing:

Understanding Starting Capacitors for Compressors: A Comprehensive Guide

Introduction

Starting capacitors play a crucial role in the efficient operation of compressors, especially in single-phase motors. They help generate the necessary starting torque and ensure smooth operation. This guide provides a detailed overview of starting capacitors, their importance, and how to select the right one for your compressor. We’ll also explore key specifications and troubleshooting tips to ensure optimal performance.

1. What is a Starting Capacitor?

A starting capacitor is an electrical component used in single-phase motors to create a phase shift, which generates the torque needed to start the motor. Without a starting capacitor, single-phase motors would struggle to start due to insufficient torque.

2. Key Functions of Starting Capacitors

- Generate Starting Torque: Provides the necessary torque to start the compressor motor.

- Phase Shift Creation: Creates a 90-degree phase shift to simulate a second phase in single-phase motors.

- Smooth Operation: Ensures the motor starts smoothly without excessive current draw.

3. Table: Starting Capacitor Specifications for Compressors

| Compressor Model | Power (W) | Voltage (V) | Capacitance (µF) | Max. Current (A) | Release Current (A) |

|---|---|---|---|---|---|

| BSA15 | 150 | 230 | 10 | 1.55 | 1.6 |

| BSA10 | 250 | 230 | 15 | 2.43 | 2.07 |

| B10A19 | 300 | 230 | 20 | 3.0 | 2.56 |

| B12A12 | 350 | 230 | 25 | 3.5 | 2.95 |

| B16A13 | 500 | 230 | 30 | 5.15 | 4.85 |

| B9A11 | 750 | 230 | 35 | 7.0 | 5.9 |

4. How to Calculate the Right Capacitor for Your Compressor

The capacitance of a starting capacitor is critical for optimal performance. Here’s a simple formula to calculate the required capacitance:

Formula:

C=P×1062πfV2cos(ϕ)C=2πfV2cos(ϕ)P×106

Where:

- CC = Capacitance (in microfarads, µF)

- PP = Motor power (in watts, W)

- ff = Frequency (in hertz, Hz, typically 50 or 60 Hz)

- VV = Voltage (in volts, V)

- cos(ϕ)cos(ϕ) = Power factor (typically 0.85 for motors)

Example Calculation:

For a motor with:

- Power (PP) = 150 W

- Voltage (VV) = 230 V

- Frequency (ff) = 50 Hz

- Power factor (cos(ϕ)cos(ϕ)) = 0.85

C=150×1062π×50×2302×0.85≈10.61 μFC=2π×50×2302×0.85150×106≈10.61μF

In this case, a 10 µF capacitor would be ideal.

5. Common Issues with Starting Capacitors

- Failed Capacitor: A faulty capacitor can prevent the motor from starting or cause it to overheat.

- Incorrect Capacitance: Using a capacitor with the wrong capacitance can lead to insufficient torque or excessive current draw.

- Overheating: Poor ventilation or excessive load can cause the capacitor to overheat and fail.

6. Troubleshooting Tips

- Check Continuity: Use a multimeter to test the capacitor for continuity. A failed capacitor will show no continuity.

- Measure Capacitance: Use a capacitance meter to ensure the capacitor’s value matches the required specifications.

- Inspect for Physical Damage: Look for bulging, leaks, or burn marks on the capacitor, which indicate failure.

- Test Under Load: Ensure the compressor starts smoothly and does not draw excessive current during startup.

7. Advantages of Using the Right Starting Capacitor

- Improved Motor Lifespan: Reduces stress on the motor during startup.

- Energy Efficiency: Minimizes power consumption during operation.

- Reliable Performance: Ensures consistent and reliable compressor operation.

8. Conclusion

Selecting the right starting capacitor for your compressor is essential for ensuring efficient and reliable operation. By understanding the specifications, calculating the correct capacitance, and performing regular maintenance, you can extend the lifespan of your compressor and avoid costly repairs.