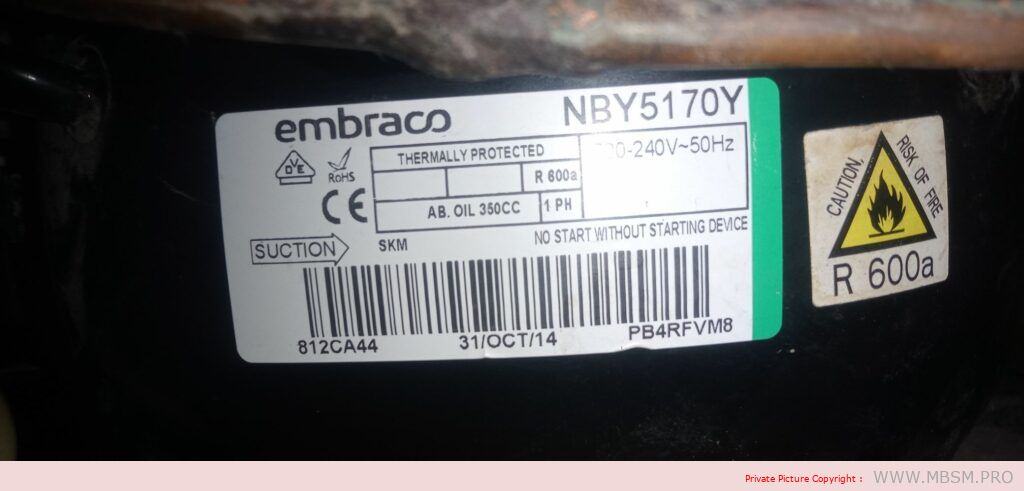

Mbsm.pro, NBY5170Y, Compressor, Cooling, 1/4 HP, 1ph 220-240V/50Hz, R600a, 15kg, High Back Pressure, HBP, Commercial Refrigeration, Embraco

Comprehensive Overview of the NBY5170Y Compressor

The NBY5170Y is a high-performance compressor designed for refrigeration and air conditioning applications. Manufactured by Embraco, a leading name in the HVACR industry, this compressor is engineered to deliver reliable and efficient cooling performance. Below, we delve into the key features, specifications, and applications of the NBY5170Y compressor.

Key Features

- High Cooling Capacity: The NBY5170Y is designed to handle demanding cooling tasks, making it suitable for both commercial and industrial applications.

- Energy Efficiency: With a high efficiency rating (W/W), this compressor ensures optimal performance while minimizing energy consumption.

- Robust Construction: Built to withstand harsh operating conditions, the NBY5170Y offers durability and long service life.

- Versatile Applications: This compressor is suitable for a wide range of refrigeration and air conditioning systems, including commercial refrigerators, freezers, and air conditioning units.

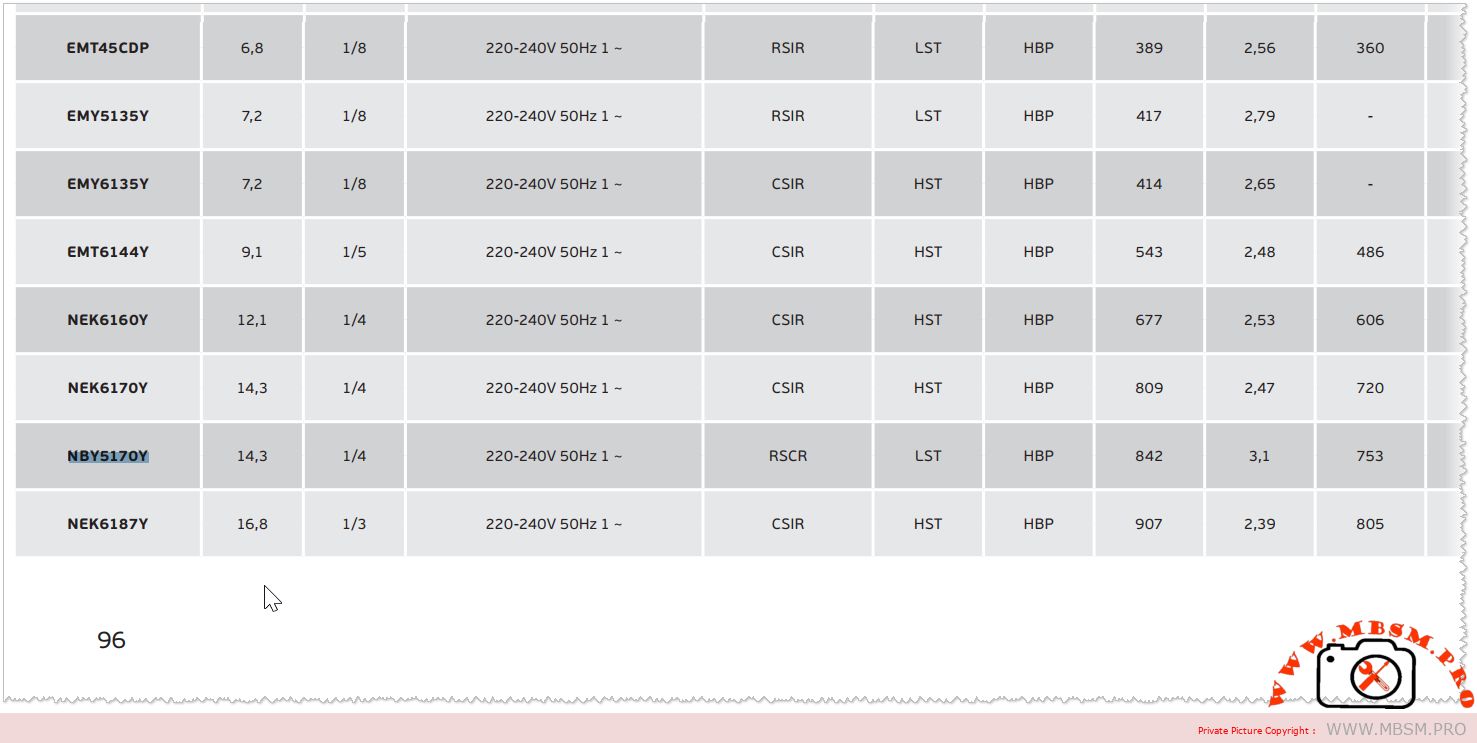

Technical Specifications

- Model: NBY5170Y

- Displacement: 14.3 cm³

- Motor Type: RSCR (Reluctance Start Capacitor Run)

- Power: 1/4 HP

- Voltage/Frequency: 220-240V / 50Hz

- Cooling Capacity: 842 W (at ASHRAE nominal point)

- Efficiency: 3.1 W/W

- Refrigerant: R600a (Isobutane)

- Oil Type: AB 5

- Weight: 15 kg

- Maximum Height: 206 mm

- Locked Rotor Amps (LRA): 15 A

- Application: High Back Pressure (HBP) systems

Performance Data

The NBY5170Y compressor is designed to operate efficiently across a range of temperatures. Here are some key performance metrics:

- Nominal Point (ASHRAE): 7.2°C Evaporation Temperature / 54.4°C Condensation Temperature

- Cooling Capacity Range: Varies based on operating conditions, with a maximum capacity of 842 W at the nominal point.

- Efficiency Range: The compressor maintains high efficiency across different load conditions, ensuring energy savings.

Applications

The NBY5170Y compressor is ideal for various applications, including:

- Commercial Refrigeration: Suitable for medium to large commercial refrigerators and freezers.

- Air Conditioning: Can be used in air conditioning systems requiring high cooling capacity.

- Heat Pumps: Effective in heat pump systems for both heating and cooling.

Installation and Maintenance

- Installation: Ensure proper mounting and alignment to avoid vibrations and noise. Follow the manufacturer’s guidelines for electrical connections and refrigerant piping.

- Maintenance: Regular maintenance is crucial for optimal performance. This includes checking oil levels, inspecting electrical connections, and ensuring the compressor is free from debris.

Conclusion

The NBY5170Y compressor by Embraco is a reliable and efficient solution for demanding refrigeration and air conditioning applications. Its robust design, high cooling capacity, and energy efficiency make it a preferred choice for commercial and industrial use. Whether you are upgrading an existing system or installing a new one, the NBY5170Y offers the performance and reliability you need.

For more detailed information, including wiring diagrams and specific installation instructions, refer to the official Embraco documentation or consult with a certified HVACR technician.