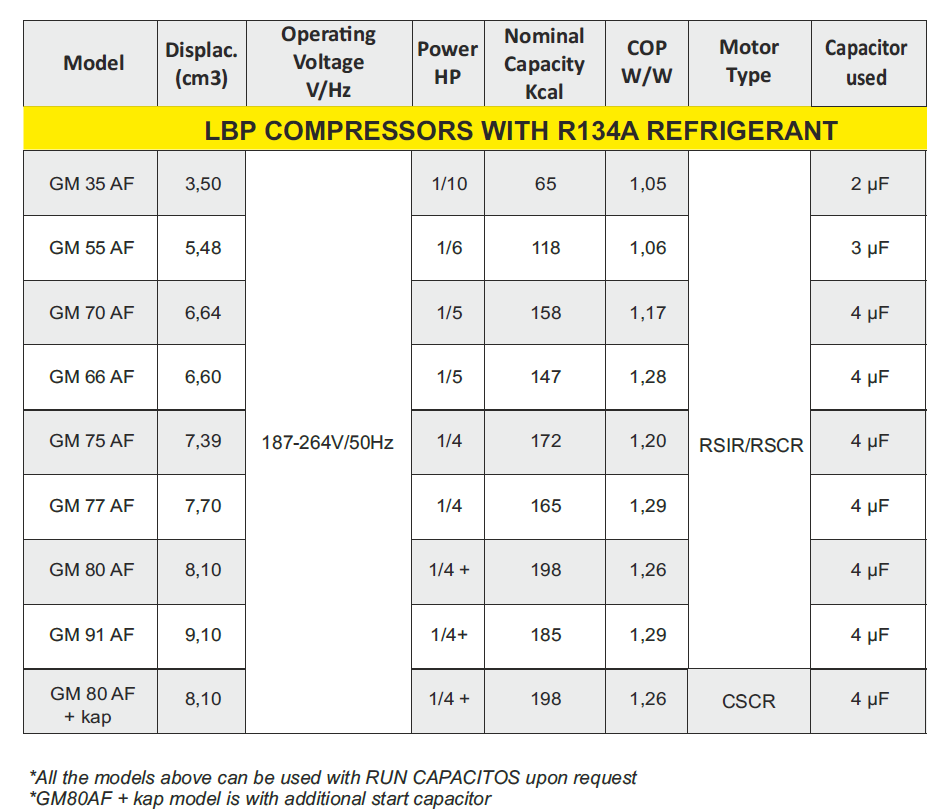

Mbsm.pro, Compressor, GM35AF, GM55AF, GM70AF, GM66AF, GM75AF, GM77AF, GM80AF, GM91AF, GM80AF

LBP Compressors with R134A Refrigerant: A Comprehensive Overview

LBP compressors, renowned for their reliability and efficiency, are widely used in various refrigeration applications. This article delves into the specifications of a range of LBP compressors that utilize R134A refrigerant, providing detailed information on their performance parameters and operational characteristics.

Table of Specifications

The table below outlines the key specifications for each model of the LBP compressors:

Key Features and Performance Metrics

- Displacement : The displacement values range from 3.50 cm³ to 9.10 cm³, indicating the volume of refrigerant that can be compressed per cycle. Higher displacement models like GM 91 AF are suitable for larger cooling capacities.

- Operating Voltage : All models operate within the voltage range of 187-264V at a frequency of 50Hz, ensuring compatibility with standard electrical supplies.

- Power HP : The power ratings vary from 1/10 HP to 1/4+ HP, reflecting the energy consumption and output capacity of each compressor. Models with higher power ratings, such as GM 80 AF and GM 91 AF, are designed for more demanding applications.

- Nominal Capacity : The nominal cooling capacities range from 65 Kcal to 198 Kcal, catering to different cooling requirements. For instance, the GM 80 AF and GM 80 AF + kap models both offer a high cooling capacity of 198 Kcal.

- COP (Coefficient of Performance) : The COP values indicate the efficiency of the compressors, with higher values signifying better performance. The GM 66 AF model boasts a COP of 1.28, making it one of the most efficient in the lineup.

- Motor Type : Most models feature RSIR/RSCR motor types, known for their robustness and reliability. The GM 80 AF + kap model, however, uses a CSCR motor type, which may offer additional benefits depending on the application.

- Capacitor Used : The capacitors used range from 2 µF to 4 µF, aiding in the starting and running of the motors. The GM 80 AF + kap model, with its additional start capacitor, ensures smoother operation under varying load conditions.

Additional Notes

- All the models listed can be equipped with RUN CAPACITORS upon request, enhancing their performance and longevity.

- The GM 80 AF + kap model is specifically designed with an additional start capacitor, making it ideal for applications requiring enhanced starting torque.

In conclusion, the LBP compressors with R134A refrigerant offer a versatile range of options to meet diverse cooling needs. Their robust design, coupled with high efficiency and reliability, makes them a preferred choice for various refrigeration systems.