Mbsm.pro, Compressor, P14TY, 3/8 hp, Cooling, hmbp, r12, 1ph220v

The P14TY is a refrigerant compressor model listed in the provided datasheet, designed for use in refrigeration or air conditioning systems. Below is a summarized technical breakdown of its key specifications:

P14TY Compressor Specifications

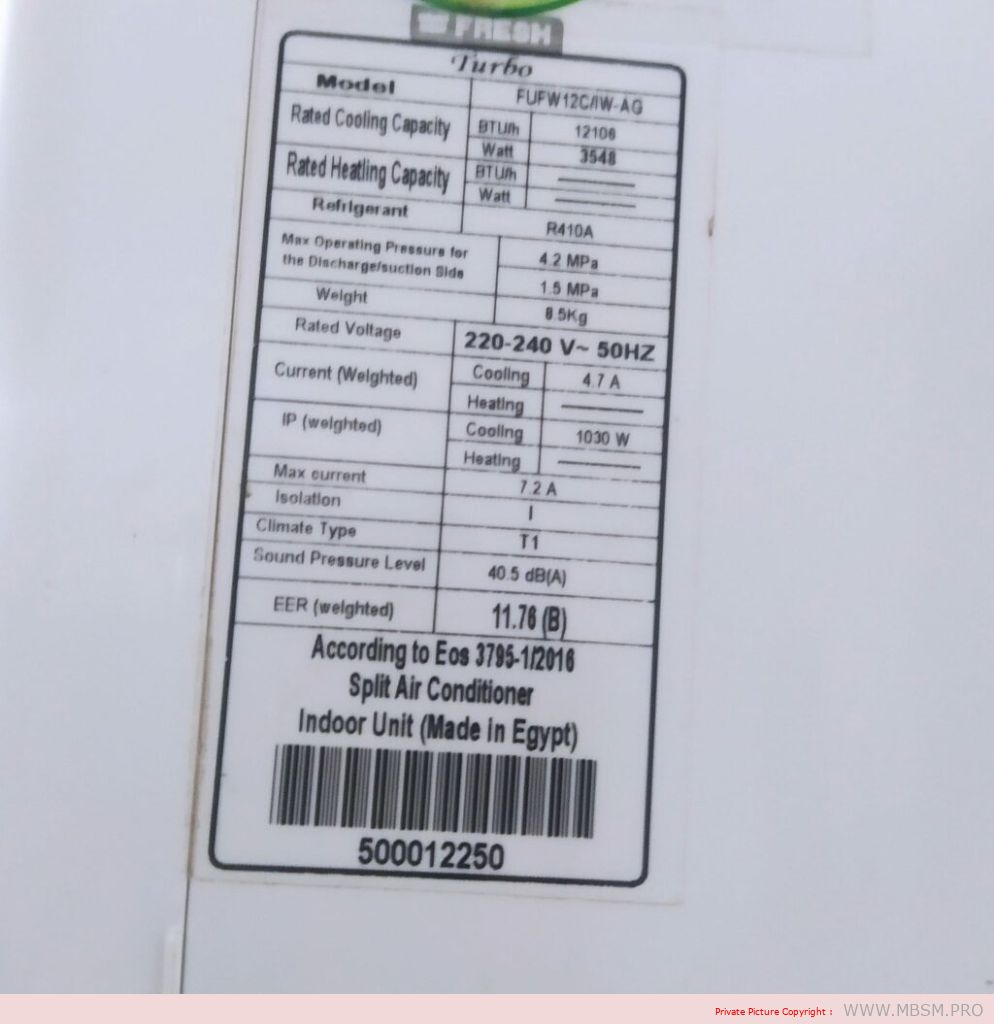

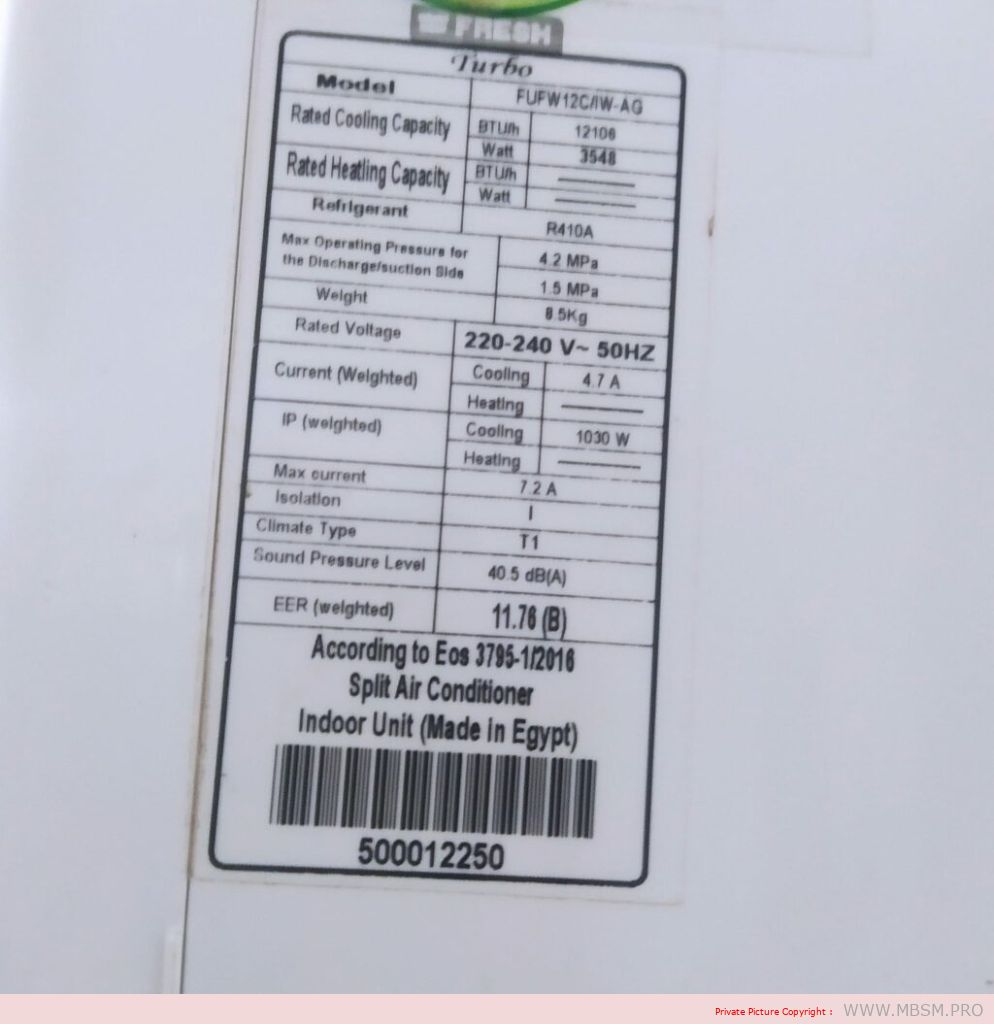

| Parameter | Value | Notes |

|---|---|---|

| Model | P14TY | Part of a series (likely Panasonic or similar brand). |

| Power (HP) | 3/8 HP | ~0.375 horsepower. |

| Displacement | 14.00 cm³ | Cylinder volume per revolution. |

| Refrigerant | R12 (CFC) | Older refrigerant (now phased out; check local regulations). |

| Cooling Capacity | – W: 985 W – kcal/h: 996 – BTU/h: ~3,360 |

At -25°C evaporating temp (CECOMAF conditions). |

| COP (Efficiency) | 1.73 (W/W) | Coefficient of Performance. |

| Oil Type/Volume | 400 cm³ | Mineral or alkylbenzene oil (for R12). |

| Weight | 11.5 kg | |

| Motor Type | CSIR (Capacitor Start, Induction Run) | Single-phase operation. |

| Starting Method | Relay (R) | |

| Voltage/Frequency | 220-240V, 50Hz | Single-phase AC. |

| Expansion Type | Capillary tube (C) or Valve (V) | Configurable based on application. |

Key Observations

- Refrigerant (R12):

- The P14TY is designed for R12, an obsolete CFC refrigerant banned under the Montreal Protocol due to ozone depletion. Modern alternatives (e.g., R134a, R404A) require retrofitting or replacement.

- Applications:

- Likely used in medium-temperature refrigeration (e.g., commercial refrigerators, chillers) given its capacity and COP at -25°C evaporating temperature.

- Efficiency (COP 1.73):

- Lower COP compared to modern compressors, indicating higher energy consumption.

- Replacement Considerations:

- If retrofitting for alternative refrigerants, ensure compatibility with oil type (e.g., POE for HFCs) and system components.

- Verify electrical specs (voltage, starting torque) for new installations.

Testing Conditions (CECOMAF/ASHRAE)

- Evaporating Temp: -25°C (LBP testing for low-temperature applications).

- Condensing Temp: 55°C.

- Ambient Temp: 32°C.

Actionable Recommendations

- For Maintenance:

- Check oil levels and contamination if still using R12.

- Inspect capacitors/relays (common failure points in CSIR motors).

- For Replacement:

- Consider modern equivalents (e.g., Panasonic/Copeland models for R404A/R134a).

- Consult HVAC technician for system compatibility and retrofitting.