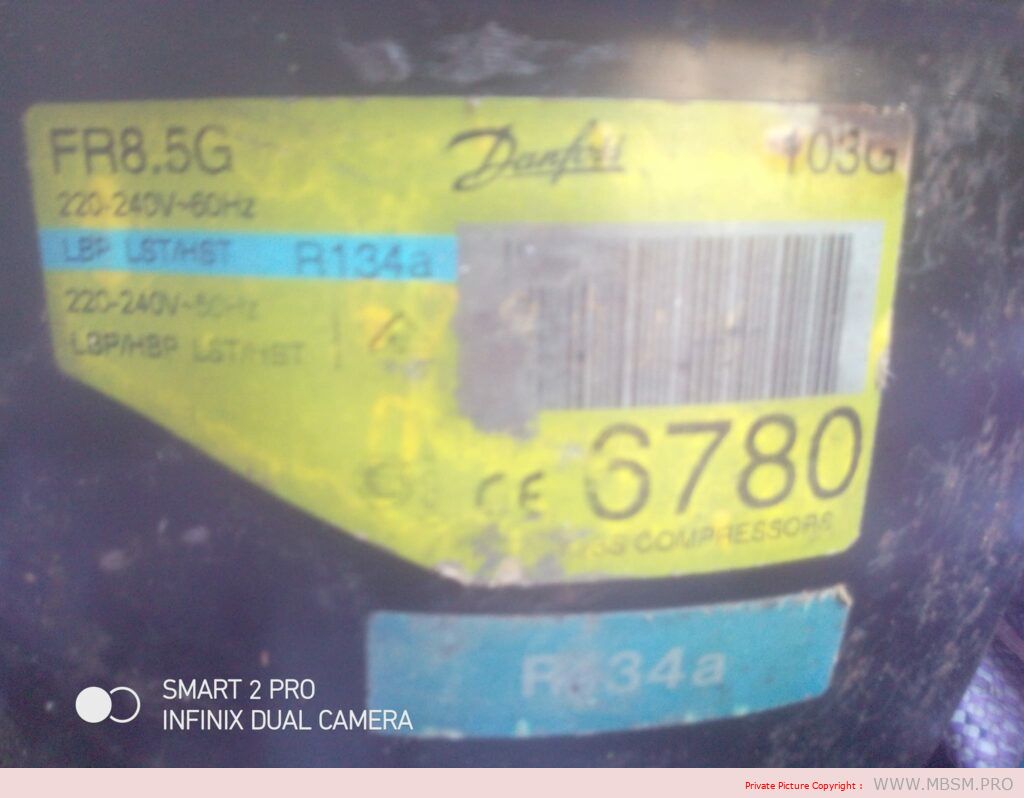

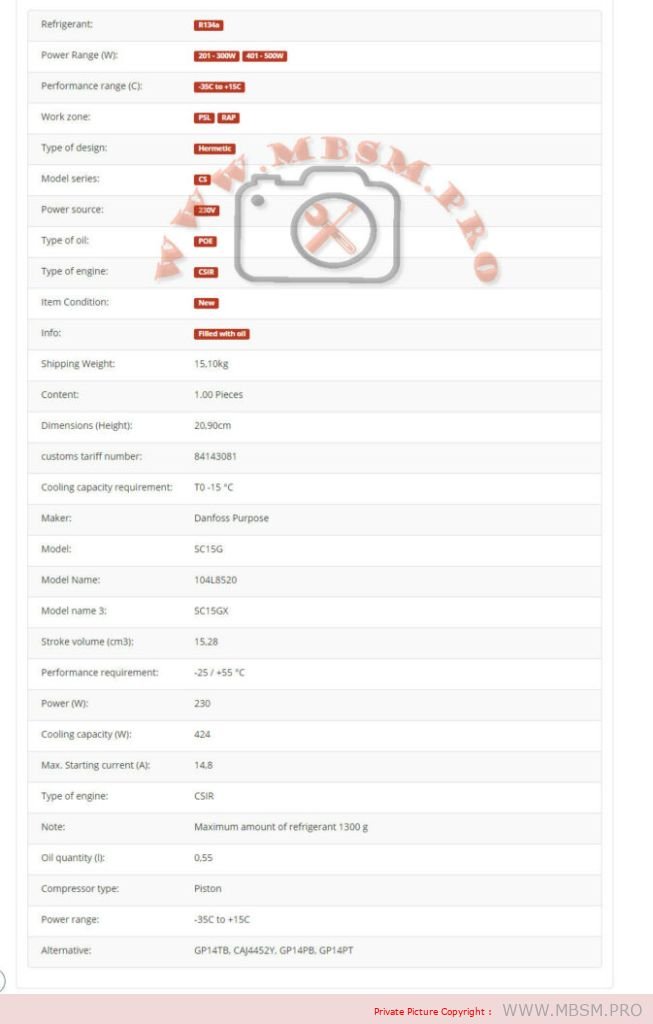

Compressor, Danfoss, fr8.5g, 103g6780, 103g 6780, 1/4 hp, LBP / HBP, r134a

103G6780, compressor Secop / Danfoss FR8.5G, LBP / HBP – R134, 220 – 240V / 1 / 50 Hz, discharge 7.95 cm3, motor type RSIR/CSIR, oil type POE, oil charge 450 cm3, 126 W at -25 / 55° C, LRA 8.2 A, maximum refrigerant charge 900 g, height: 196 mm, weight 10.6 kg

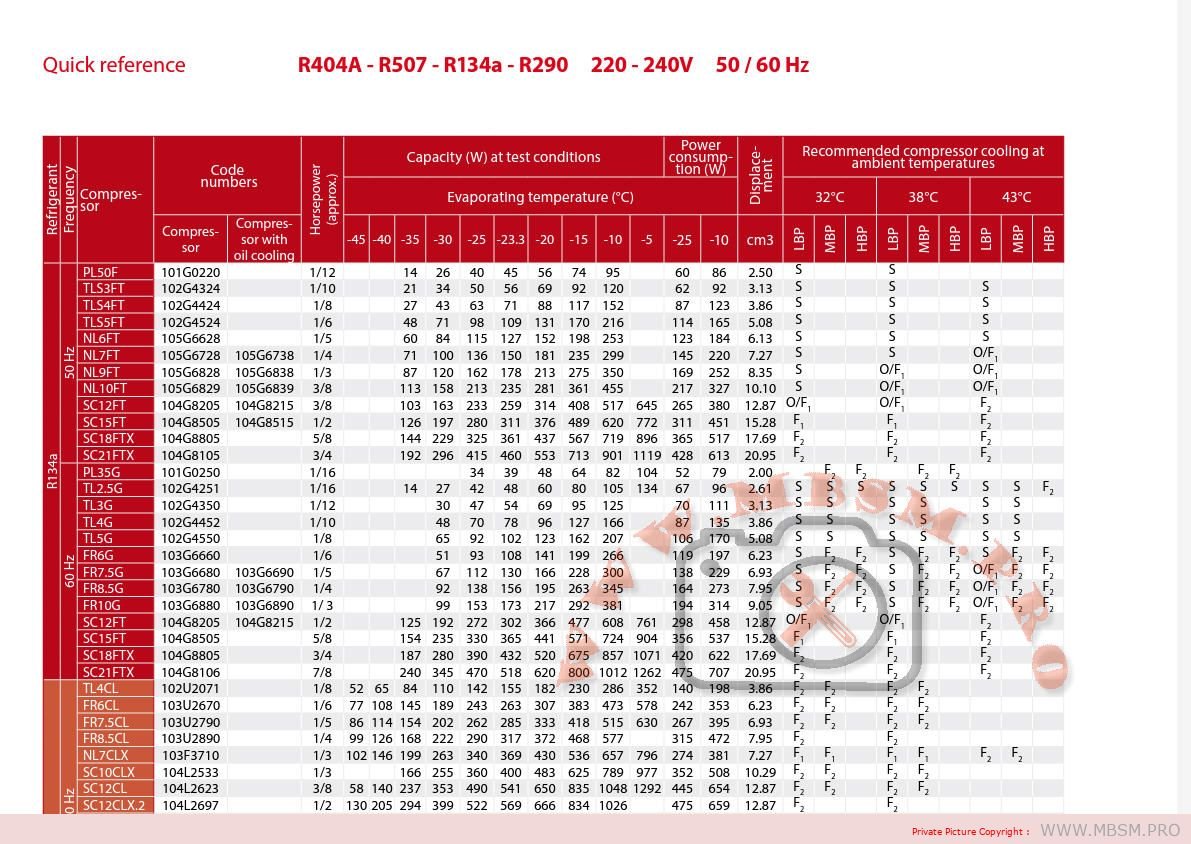

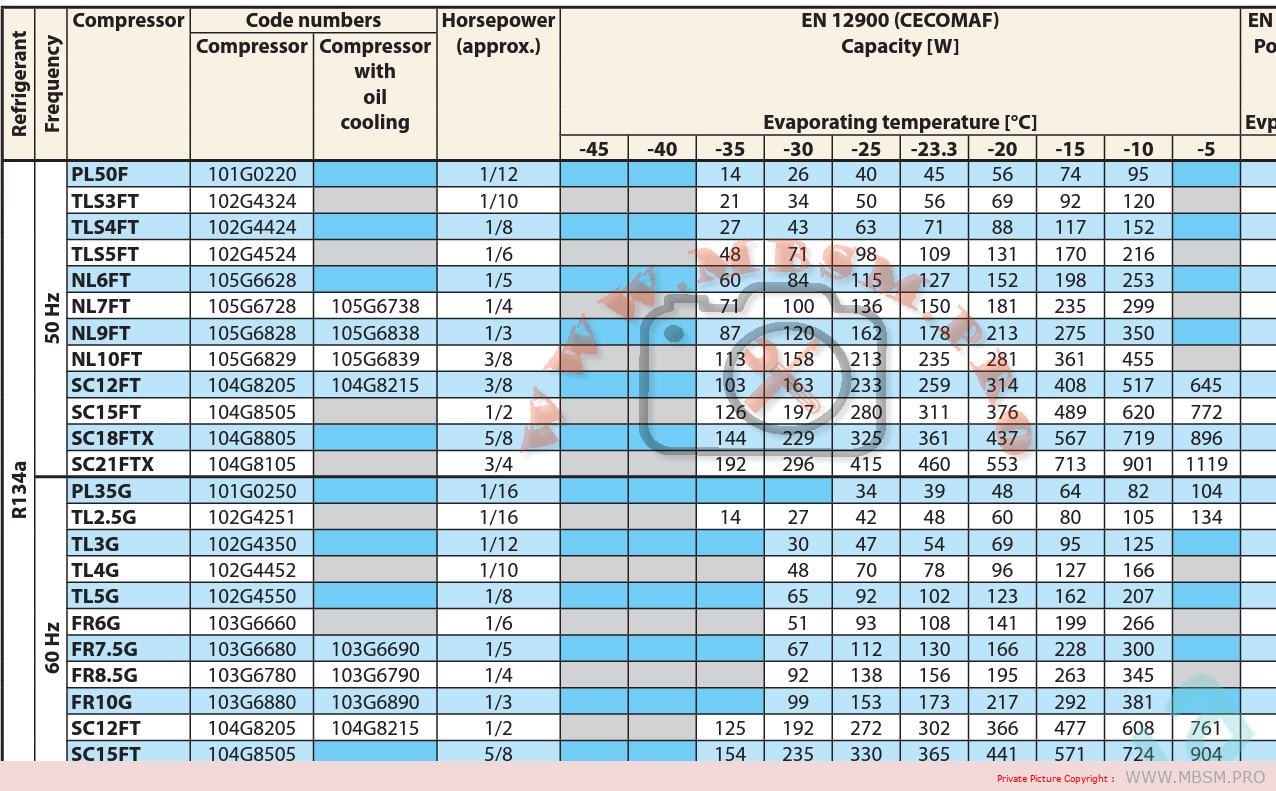

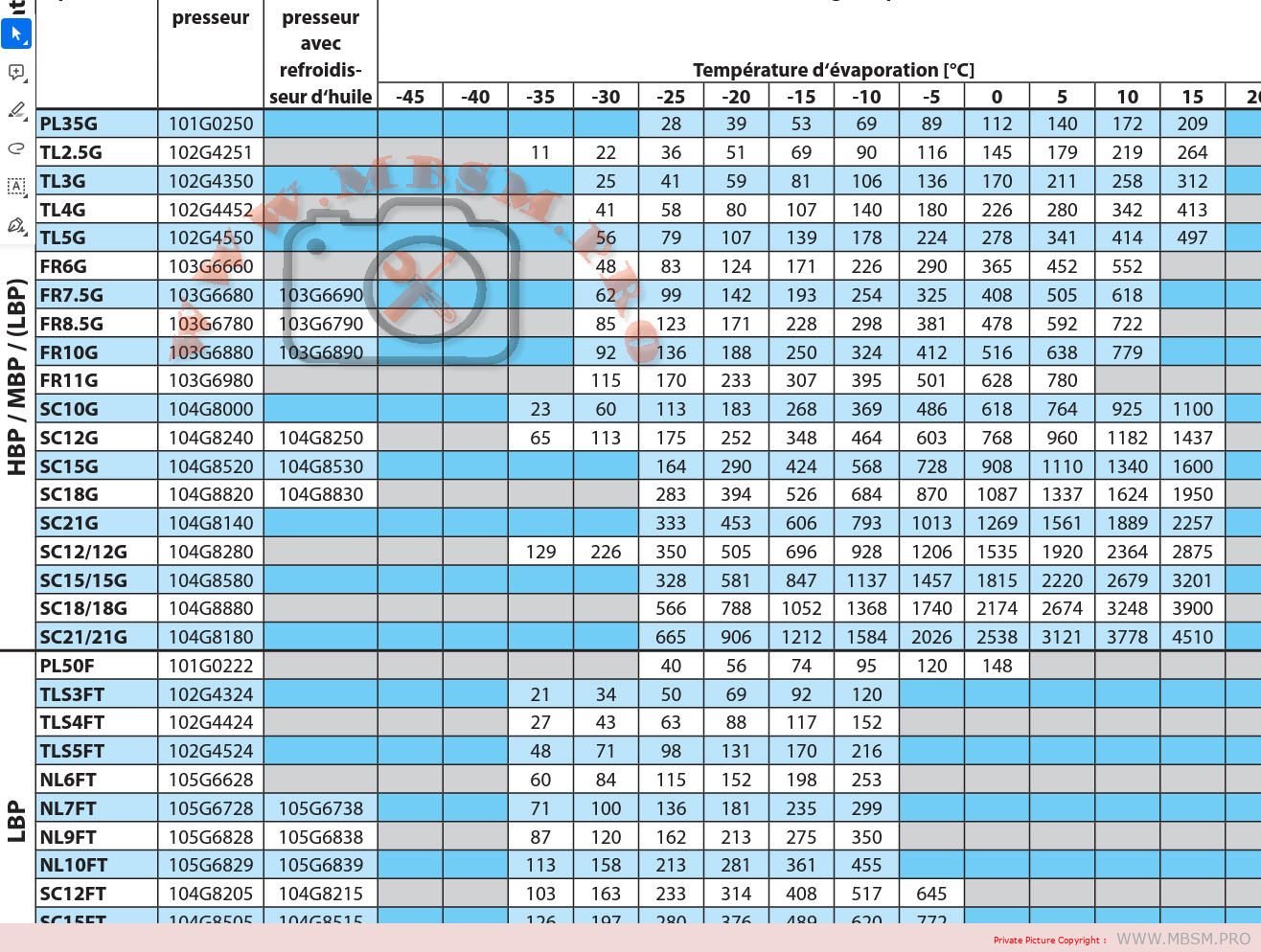

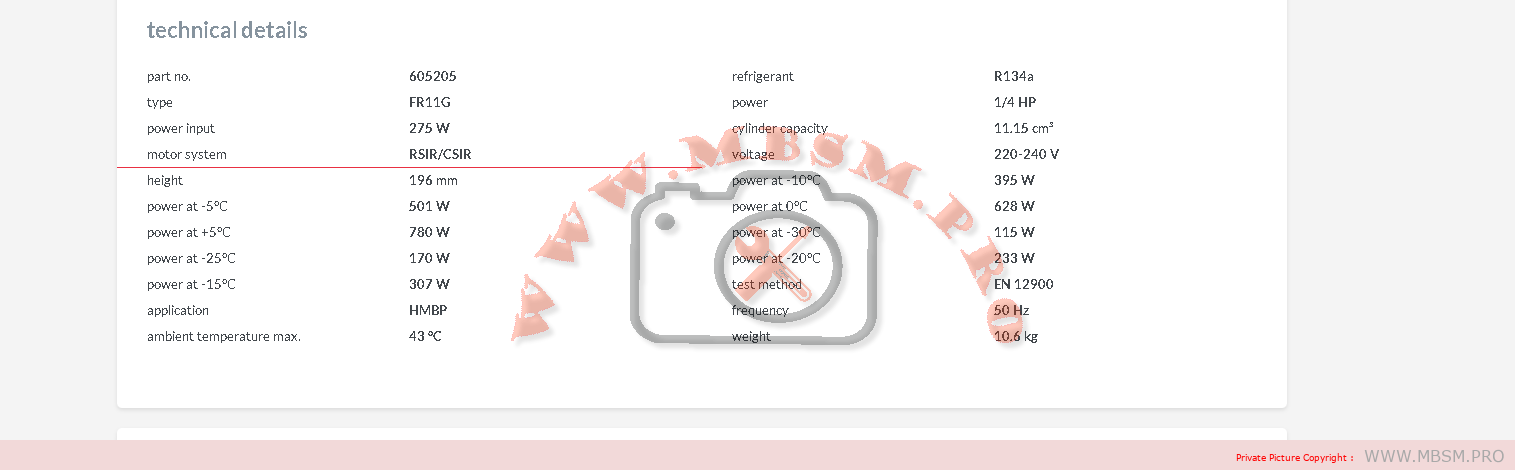

Discover the powerful FR8.5G compressor from SECOP-DANFOSS for various refrigeration applications. This compressor works with R134a refrigerant and offers an impressive output of 1/4 HP. With a power consumption of 261 W and a displacement of 7.95 cm³, it is efficient and reliable.

The FR8.5G compressor has an RSIR/CSIR motor system and works with a voltage of 220-240 V. With a height of 196 mm, it is compact and space-saving.

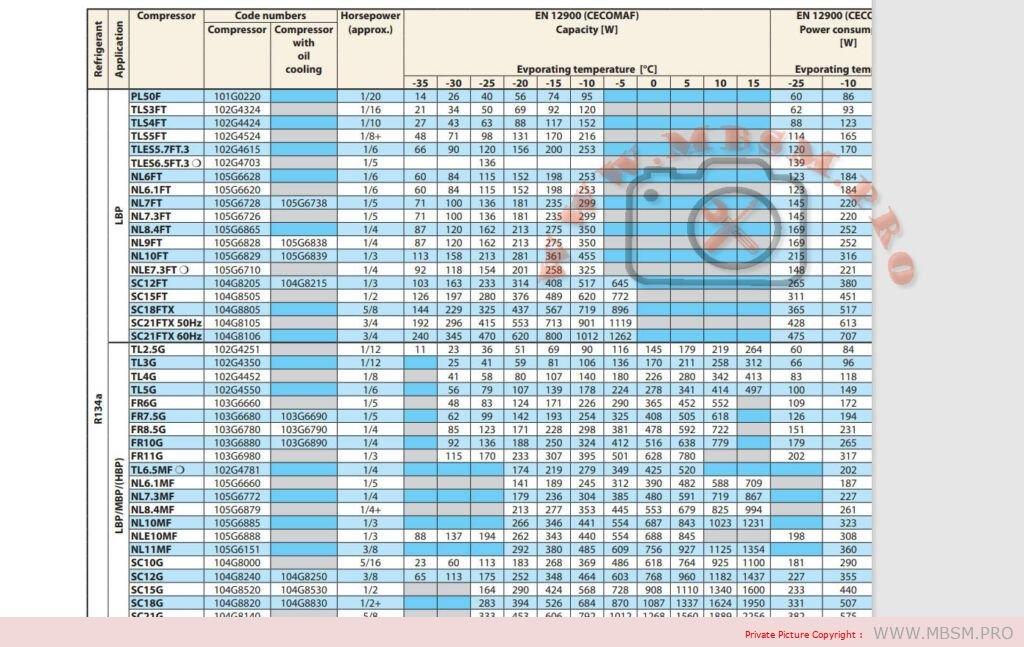

This compressor offers impressive performance at various temperatures. The performance data at -10°C, -5°C, 0°C, +5°C, -30°C, -25°C, -20°C, -15°C and +10°C show its versatility and Efficiency. It is ideal for medium and high pressure (HMBP) applications.

The FR8.5G compressor is suitable for the manufacturers Dexion and La-Sommelier and is suitable for use in refrigerators, cooling tables, refrigerated display cases and warming display cases.

Order the FR8.5G compressor from SECOP-DANFOSS today and benefit from its reliable performance and efficiency in your refrigeration applications.

Attribute list:

– Refrigerant: R134a

– Type: FR8.5G

– Power: 1/4 HP

– Power consumption: 261 W

– Displacement: 7.95 cm³

– Engine system: RSIR/CSIR

– Voltage: 220-240V

– Height: 196mm

– Power at -10°C: 298 W

– Power at -5°C: 381 W

– Power at 0°C: 478 W

– Power at +5°C: 592 W

– Power at -30°C: 85 W

– Power at -25°C: 123 W

– Power at -20°C: 171 W

– Power at -15°C: 228 W

– Power at +10°C: 722 W

– Application: HMBP

– Frequency: 50Hz

– Weight: 10.6kg