A capacitor is a device used to store an electric charge, consisting of one or more pairs of conductors separated by an insulator.

Unexpectedly the electrolytic capacitors explodes with huge sound and sometime it smoke.

Get started , how to explode a capacitor ???

All capacitors have a maximum voltage and their destruction depends upon the internal construction. Explosions are understood only by delving into the internal construction of electrolytic capacitors – the primary culprit.

Most small value capacitors are simple sandwiches of conductor and insulator and when the voltage exceeds the dielectric strength of the insulation, they short out and burn, crack, pop, open, or smoke. Explosions are rare for these. Popping open is more likely. Their failure is self evident either visually or by failure to function in the circuit.

Most large value capacitors in order to be as small in physical size as possible, have to get the conductive plates of the capacitor as close together as possible and at the same time not so small that the voltage rating is impractical.

It is for this reason that the family of electrolytic capacitors was developed. The trick they use to get high capacity with small separations and reasonable voltage is that they use the “anodizing” of chemical electrolysis on one surface and a water based electrolyte for the other surface. Take one apart and see.

Notice that when a conductive metal is “anodized” by electrochemical process it turns into a dull film that is rather tough and is an insulator. This means that the actual conductive plate of the capacitor has this film entirely between itself and the other plate.

Then the other plate uses a trick too. There’s a water base solution soaked into a paper separator. Now if there was no water, the paper would be the dielectric of a normal capacitor separating the plates. But not here. Here the water has an alkali added to become a fair conductor. And as a liquid it soaks right into the surface structures of the capacitor. So it’s not the paper thickness at all – and not even the insulating surface on the other plate, but the inner recesses of the anodized surface that determine the dielectric distances.

So the operating voltage that a capacitor can tolerate depends upon how thick this anodized film is. And that is a function of it’s manufacture. Now there is a most useful characteristic that tells us we are nearing the max voltage, called leakage.

Here is a way you can check this out. Put in series, a test electrolytic capacitor (polarize it correctly), a variable power supply, a microammeter, and a 1 meg resistor (to limit and protect the meter). From zero as you increase the voltage there will be no current initially, then as you approach the spec op voltage, there will start a small leakage current. Since you have a limiting resistor here, you can increase the voltage without damage. continuing to increase the voltage discovers an increasing leakage current. It is a matter of practice how much safety you apply between the rating and the actual voltage of the circuit.

You can now see how it is that an electrolytic capacitor fails, it is not a voltage breakdown of the dielectric material, but the increase of leakage current that is troublesome. A rising leakage means heat which will boil the water and make steam – that’s the explosion process.

This is explosion as occasional failure of the few. But there is a more spectacular explosion process – it’s explosion by mistake – namely being installed backward. In such a case, the anodizing chemistry is reversed and rather rapidly, the anodized film starts to reverse, and quickly thins out at a weak spot in the rather large effective film area of the capacitor. Then we have short circuit currents and steam generation rather quickly. This sort of explosion usually fills the space (the casing or the whole room if exposed) with little shreads of aluminum foil and alkali soaked paper.

This insightful solution is most successful to achieve capacitors with large values in small spaces, but has a lot of lesser characteristics as the price to pay.

The worst limit, is storage. Electrolytic capacitors store very poorly, and the voltage rating can reduce substantially as the internal chemistry deteriorates. Some equipment manufacturers recommend that capacitors stored for a few years have their inner anodizing conditions restored by simply putting them to the spec voltage for a day to restore full spec.

At the least, if you replace capacitors with old stock, and it didn’t explode when power was restored, be aware that it may not reach it’s spec capacity value for a few hours. A capacitor in use will always be maintained by the voltage in the circuit you use it in.

When electrolytics are used without the circuit supplying a maintenance voltage to keep the anodized film that all depends upon, such as in speaker cross over applications that have no sustaining DC, then the values of the capacitor will deteriorate at least at storage rates, and if AC currents are substantial, even faster.

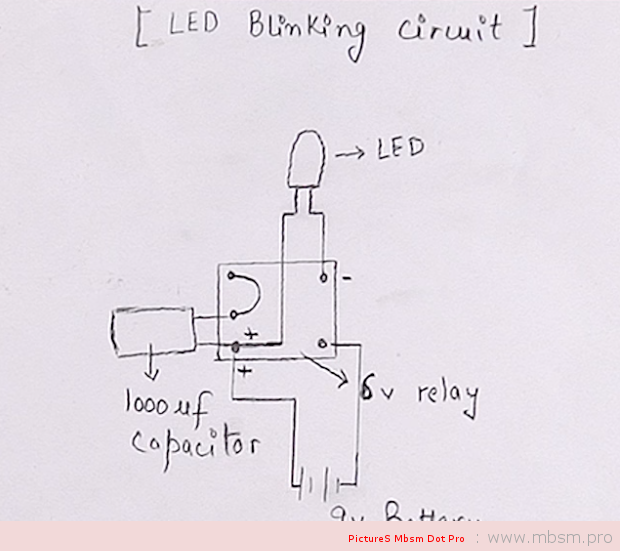

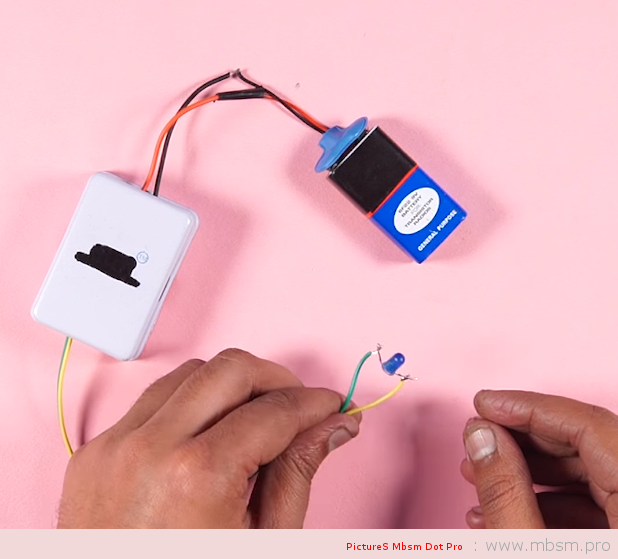

mbsm-dot-pro-capacitor-explodes- Pictures-A.jpg (4 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-A.jpg (1 MB)

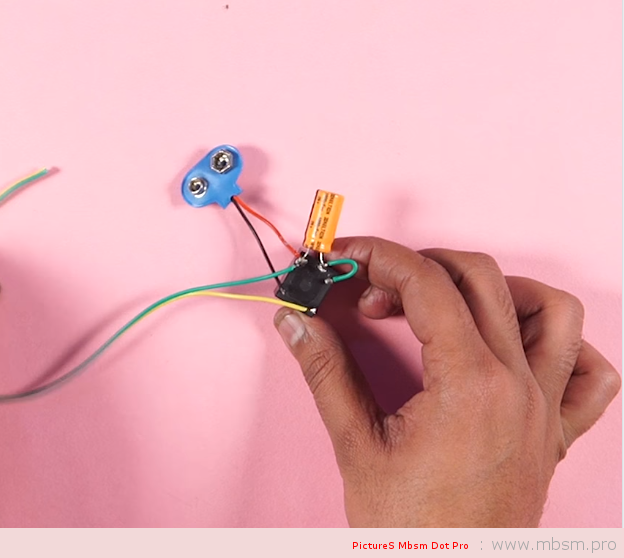

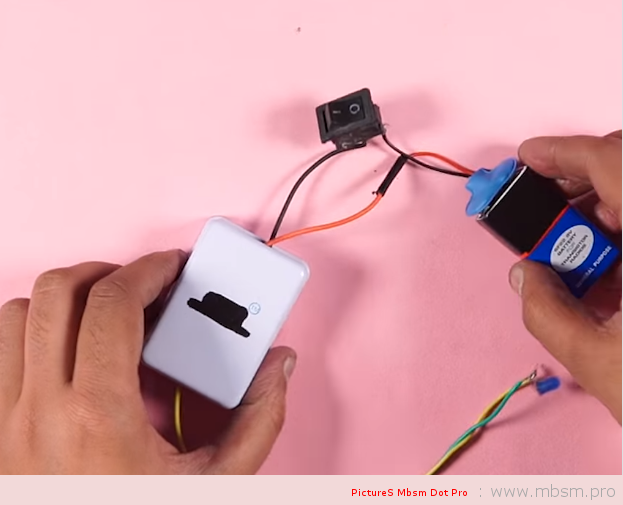

mbsm-dot-pro-capacitor-explodes- Pictures-B.jpg (3 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-B.jpg (1 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-C.jpg (3 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-C.jpg (1 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-D.jpg (3 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-D.jpg (1 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-F.jpg (2 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-F.jpg (748 KB)

mbsm-dot-pro-capacitor-explodes- Pictures-E.jpg (3 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-E.jpg (1 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-G.jpg (2 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-G.jpg (856 KB)

mbsm-dot-pro-capacitor-explodes- Pictures-H.jpg (2 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-H.jpg (690 KB)

mbsm-dot-pro-capacitor-explodes- Pictures-I.jpg (2 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-I.jpg (1 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-J.jpg (2 MB)

mbsm-dot-pro-capacitor-explodes- Pictures-J.jpg (739 KB)

.jpg)

-200x200.jpg)

.jpg)

-200x200.jpg)

.jpg)

-200x200.jpg)

.jpg)

-200x200.jpg)

.jpg)

-200x200.jpg)

.jpg)

-200x200.jpg)

.jpg)

-200x200.jpg)

.jpg)

-200x200.jpg)

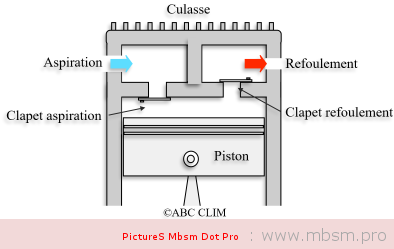

Essai des clapets de refoulement.

Essai des clapets de refoulement.